- Production Machines

- Cutting Machine

- Knife cutting machine

- Jinan AOL CNC Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

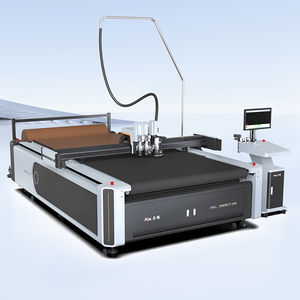

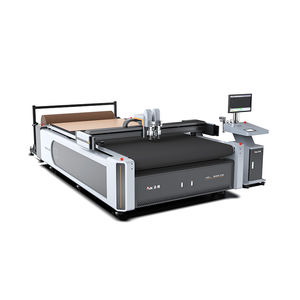

Knife cutting machine AOL-1625for foamhigh-precision

Add to favorites

Compare this product

Characteristics

- Technology

- knife

- Material

- for foam

- Other characteristics

- high-precision

- Cutting speed

Max.: 1,400 mm/s

Min.: 0 mm/s

- Overall length

3,600 mm

(142 in)- Overall width

2,400 mm

(94 in)- Height

1,200 mm

(47 in)

Description

The Styrofoam cutting machine(polystyrene foam plastic cutter) can cut straight lines and special-shaped patterns. Compared with manual cutting, it has fast speed and high precision. One piece of equipment can replace 4-6 laborers, which solves the problems of difficult recruitment, high labor costs and slow cutting efficiency !

1. Digital operation: Using vibrating knife cutting technology, no need to make molds, intelligent cutting has entered the era of digital processing.

2. High precision: The Styrofoam cutter adopts Taiwan linear guide drive system, with an accuracy of ±0.1mm

3. Multiple tool options: The Styrofoam cutting machine can be equipped with multiple tools, which are used for material cutting in different industries and increase the added value of the enterprise.

4. Intelligent typesetting: The system intelligently optimizes typesetting and cutting, provides better cutting and filling paths, and saves more than 30% of materials.

5. Ultra-high efficiency: using Japanese Panasonic servo system, the production efficiency is increased by more than 5 times

6. High safety: the whole machine is equipped with anti-static system to protect the safety of personnel to the greatest extent

7. Special-shaped cutting: It can complete the pattern cutting that is difficult, complicated in style, and cannot be realized by die-cutting machines.

8. Automatic tool setting: It has a fast and simple automatic tool setting system, and uses a fiber laser sensor to accurately detect the tool, which greatly improves the tool setting efficiency.

Catalogs

2024 AOLCNC CUTTING MACHINE

4 Pages

Other Jinan AOL CNC Equipment Co., Ltd products

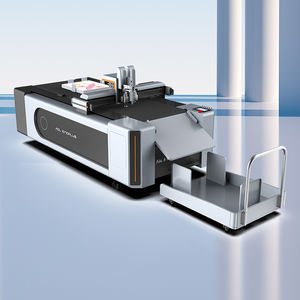

Digital Advertising Printing Cutter

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- High-efficiency cutting system

- Three-phase cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.