- Production Machines

- Cutting Machine

- Knife cutting machine

- Jinan AOL CNC Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

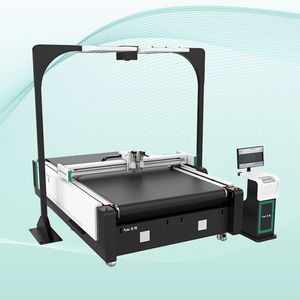

Knife cutting machine AOL-1625Dfor plasticsfor fabricsfor composite materials

Add to favorites

Compare this product

Characteristics

- Technology

- knife

- Material

- for plastics, for fabrics, for composite materials

- Product handled

- for plastic pipes, single-ply fabric, adhesive tape, for flexible PU foam blocks, for gaskets, plastic bags, cardboard box seal, for thick multi-ply fabrics, for printed circuit boards, for leather

- Control type

- CNC

- Associated function

- multi-function

- Applications

- for industrial applications, for aeronautical applications, for the electronics industry, for the toy industry, laboratory, for the plastics industry

- Workpiece loading

- automated loading/unloading

- Configuration

- large-format, flatbed, multi-head

- Other characteristics

- economical, automatic, CE, high-efficiency, high-power, ISO, with automatic feeder, FDA, with CCD camera, 45°, for technical textiles

- X travel

Max.: 2,500 mm

(98.43 in)1,600 mm

(62.99 in)Min.: 1,400 mm

(55.12 in)- Y travel

Max.: 4,500 mm

(177.17 in)2,500 mm

(98.43 in)Min.: 1,400 mm

(55.12 in)- Z travel

Max.: 100 mm

(4 in)50 mm

(2 in)Min.: 0 mm

(0 in)- Maximum cutting height

Max.: 100 mm

(3.9 in)30 mm

(1.2 in)Min.: 1 mm

(0 in)- Tube diameter

Max.: 30 mm

(1 in)15 mm

(1 in)Min.: 1 mm

(0 in)- Cutting speed

Max.: 3 m/s

(9.843 ft/s)1 m/s

(3.281 ft/s)Min.: 0.1 m/s

(0.328 ft/s)- Laser power

Max.: 5,500 W

1,500 W

Min.: 500 W

- Repeatability

5 mm

(0.1969 in)- Resolution

Max.: 300 dpi

150 dpi

Min.: 72 dpi

- Acceleration

Max.: 10 m/s²

(33 ft/s²)5 m/s²

(16 ft/s²)Min.: 1 m/s²

(3 ft/s²)- Operating pressure

Max.: 6,500 bar

(94,274.53 psi)2,500 bar

(36,259.43 psi)Min.: 200 bar

(2,900.75 psi)- Overall length

2,200 mm

(87 in)- Overall width

3,100 mm

(122 in)- Height

1,221 mm

(48 in)- Weight

Max.: 2,400 kg

(5,291.09 lb)1,500 kg

(3,306.93 lb)Min.: 1,200 kg

(2,645.55 lb)

Description

The gasket cutting machine does not need to be punched. It only needs to import the data into the system to identify and cut the material. The automation of this step directly saves a lot of time and cost.

The cutting machine typesetting software can accurately complete the typesetting without manual layout. After a lot of tests, the use of the gasket cutting machine can save more than 10% of materials compared to manual work. The cutting is more precise. In the process of cutting, the manual punch has a high probability of deviation, and the machine is supplemented by the software system, which can minimize the error.

The gasket cutting machine does not need to measure, just input the size and shape, which greatly improves the output of the manufacturer. The equipment has a high degree of automation, the operation is very simple, few workers are required, and it can work continuously for 24 hours, eliminating the problems of high labor costs and difficult recruitment.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan AOL CNC Equipment Co., Ltd‘s catalogsOther Jinan AOL CNC Equipment Co., Ltd products

Digital Gasket Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- Three-phase cutting system

- High-efficiency cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.