- Production Machines

- Forming Machine

- Drilling machining line

- Jinan Blue Elephant CNC Machinery Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

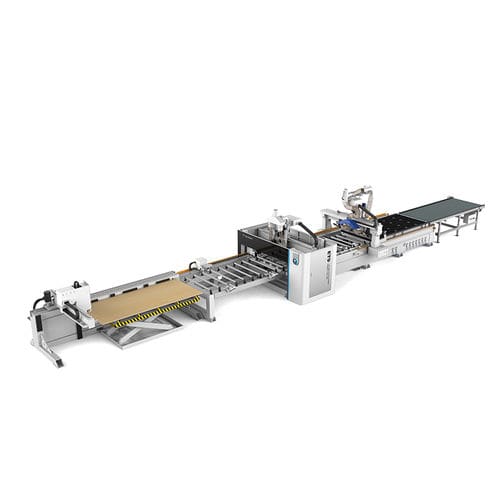

CNC machining line ET-9for wooden furnituredrillingpunching

Add to favorites

Compare this product

Characteristics

- Applications

- for wooden furniture

- Function

- drilling, punching, cutting, labeling, milling, edge-banding

- Other characteristics

- CNC

Description

ET-9 intelligent labeling CNC drilling and cutting production line is a device that integrates labeling, punching, cutting and

edge banding functions. It can be used in woodworking, wooden furniture, cabinets, interior door design and manufacturing,

construction and decoration and other industries. It optimizes the production process, reduces labor and improves efficiency.

Features

1. Optimize the production process and reduce costs. Labeling, punching and cutting are completed at one time, and then the edge

banding machine is used to punch holes, eliminating the traditional production line six-sided drilling or side hole machine

punching process. 2. Easier operation, higher degree of automation, automatic labeling, drilling and milling, automatic edge

banding and punching. 3. High processing efficiency, double drilling and punching, faster speed.

4. One-time positioning and punching, no need to flip the plate, higher processing accuracy, and save the process of flipping the

plate in the traditional production line. 5. Simplified process flow, during the production process, the process of moving and

transporting the plate is reduced, saving labor and effort, and reducing the risk of plate damage.

VIDEO

Other Jinan Blue Elephant CNC Machinery Co.,Ltd products

Nesting CNC

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.