- Metrology - Laboratory

- Metrology and Test Equipment

- Electronic product drop tester

- Jinan Liangong Testing Technology Co., Ltd

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

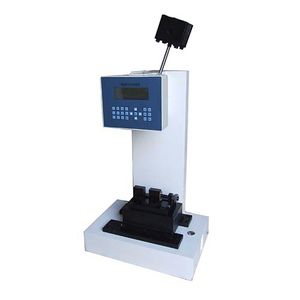

Electronic product drop tester JL-50000DWTTfor tear tests

Add to favorites

Compare this product

Characteristics

- Applications

- for electronic products

- Options

- DWTT, for tear tests

Description

1.The drop hammer impact testing machine is mainly used for ferrite steel drop weight tear test (ie DWTT). Also can be customized according to user needs in different forms of hammer and anvil to meet the requirements of other test methods.

2.The machine consists of frame part, feeding part, lifting system, hammer, anvil, safety protection system and control system. The machine can adjust the impact energy by adjusting the weight of thallium and adjusting the impact height, and the energy range is stepless adjustable.

Main technical Parameter

1 - Impact energy range - 20000J~50000J

2 - Effective use of the height range - 0 ~2m

3 - Effective use height range - 1.2~2m

4 - The maximum impact speed - ≥5m / s

5 - Hammer body basic weight - 1750kg

6 - Counterweight thallium weight - 200kg (4 pieces)

7 - The total weight of the hammer - 750kg

8 - Hammer blade radius of curvature - R25.4 ± 2.5mm

9 - Anvil roll radius of curvature - R14.3 ± 1.59mm.

10 - Hammer and roll hardness - 60 ~ 65HRC

11 - Center deviation of hammer blade center line and support span - ± 1mm

12 - Hammer lifting speed - 3m / min

13 - Lifting height indication error - ± 0.03%

14 - The centering precision of the specimen - ± 1m

15 - Anvil roll span - 254mm

16 - Host height - 5700mm.

17 - Host area (including all parts of the machine and the distance from other equipment or buildings) - 8m* 8m

18 - Total weight - About20 tons

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan Liangong Testing Technology Co., Ltd‘s catalogsOther Jinan Liangong Testing Technology Co., Ltd products

Impact Testing Machine Series

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Flexure testing machine

- Tensile test machine

- Industrial testing system

- Automatic test equipment

- Laboratory test machine

- Precision test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.