- Production Machines

- Cutting Machine

- Laser cutting machine

- Jinan Lingxiu Laser Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

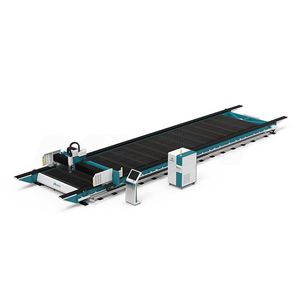

Laser cutting machine for glasssheetCNC

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for glass

- Product handled

- sheet

- Control type

- CNC

- Applications

- for industrial applications

- Other characteristics

- high-precision, high-efficiency, with water cooling, mobile

- X travel

360 mm, 450 mm, 500 mm, 600 mm

(14.17 in, 17.72 in, 19.69 in, 23.62 in)- Y travel

400 mm, 600 mm, 700 mm

(15.75 in, 23.62 in, 27.56 in)- Z travel

50 mm

(2 in)- Cutting speed

Max.: 300 mm/s

Min.: 0 mm/s

- Laser power

10 W, 30 W, 50 W, 75 W, 100 W

- Repeatability

1 µm

Description

Advantages of picosecond laser glass cutting machine

Compared with CNC processing equipment, the fragile material non-taper picosecond laser cutting machine has no consumables, no pollution, and high production efficiency (several times the processing efficiency of CNC) during the production process, which greatly saves production and manufacturing costs for processing manufacturers. , Improve product profit.

Application of Picosecond Laser Glass Cutting Machine

1. Strengthened and non-strengthened glass cutting, such as: mobile phone glass cover, car glass cover, camera glass cover, etc.;

2. Sapphire glass cutting, such as: mobile phone sapphire cover, camera sapphire glass cover, sapphire light bar (LED light bar), etc.;

3. LCD screen glass cutting, such as: special-shaped LCD screen inverted R/U/C angle, LCD screen slitting, etc.;

4. Other optical glass cutting, such as: filter cutting, mirror cutting, etc., prisms;

1. Laser:

Picosecond pulse laser (the seed sources are all the world's mainstream brands such as Germany Nlight)

2. Cutting head

Exclusive glass cutting head, all lenses imported from the United States, fine spot, long focal depth, minimum focal spot <2um, focal depth length up to 15mm;

3. Countertop

The motor platform and the base of the optical platform are made of natural marble, and the precision level reaches 00 after the second fine grinding process.

4. Drive system

X/Y axis motor adopts high-end linear motor, German 0.1um digital grating ruler, Taiwan screw and guide rail, high-quality core motion

Components, 24 hours operation without failure;

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan Lingxiu Laser Equipment Co., Ltd‘s catalogsOther Jinan Lingxiu Laser Equipment Co., Ltd products

Metal Plate Fiber Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- Metal fabrication cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- High-efficiency cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.