- Machine-tools

- Machining Center

- 4-axis machining center

- JINAN YUEFENG MACHINERY CO., LTD.

- Products

- Catalogs

- News & Trends

- Exhibitions

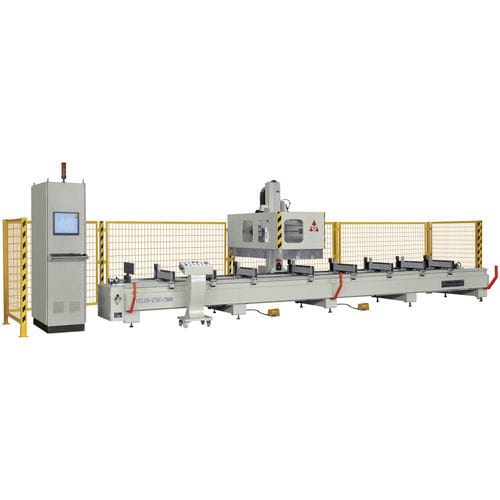

4-axis CNC machining center YFLGS-CNC-7000verticalfor aluminummilling

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- vertical

- Machined material

- for aluminum

- Associated functions

- milling, tapping, drilling

- Applications

- for aluminum profiles

- Other characteristics

- high-precision

- X travel

7,200 mm

(283.46 in)- Y travel

1,400 mm

(55.12 in)- Z travel

600 mm

(23.62 in)- Rotational speed

Min.: 0 rpm

(0 rad.min-1)Max.: 18,000 rpm

(113,097 rad.min-1)- Power

12 kW

(16.32 hp)- Work feed X-axis

Min.: 0 m/min

Max.: 60 m/min

- Work feed Y-axis

Min.: 0 m/min

Max.: 0 m/min

(0 in/s)- Work feed Z-axis

Min.: 0 m/min

Max.: 30 m/min

- Overall length

11,300 mm

(444.9 in)- Overall width

2,400 mm

(94.5 in)- Overall height

2,300 mm

(90.6 in)

Description

- This machine is mainly used for aluminum profile for taping, milling or mounting holes, lock holes, launders and other slots on the profiles of curtain walls. It can work on various profiles, such as aluminum

alloy, non-ferrous metal, orbit construct, upvc etc.

- Whole set of CNC system adopts by LENZE originally imported from Germany, including servomotor and driver. Professional quality guaranty.

- The main shaft adopts HSD imported from Italy, which can finish any angle of drilling between ±90°.

- 8 sets of chucking can locating automatically, which can avoid collision.

- Every cutter has length compensation function, which can guarantee the processing accuracy.

- Adopt professional CAD-CAM software, which is easy to operate.

- It can finish all kinds of holes processing, milling, tapping etc between one time of clamping.

- The whole machine body is made of steel tube with heat treatment, which can guarantee the inflexibility.

- It adopts HIWIN guide rails and YYC grinded gear racks which can guarantee high precision.

- It adopts FESTO, SMC, AIRTIC electrical and pneumatic products, professional quality guarantee.

- It adopts Turck proximity switchs imported from Germany and APEX, iGB speed reducer.

- The rotary tool magazine which made in Taiwan has 12 cutters, the cutters change automatically fast.

- Double worktable design, it can keep working when changing profile, high production efficiency.

- It equipped shaft location detection, operator location detection which can guarantee safe operation.

Other JINAN YUEFENG MACHINERY CO., LTD. products

Aluminum Windows and Curtain Wall Processing Machine

Related Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- 3-axis router

- Drilling machine

- Milling CNC machining center

- Aluminum CNC machining center

- Milling machine

- Drilling CNC machining center

- CNC drilling machine

- Vertical milling machine

- 4-axis CNC machining center

- PVC router

- Tapping CNC machining center

- Drilling and milling machine

- CNC drilling and milling machine

- Copy router

- End milling machine

- 4-axis router

- Drilling router

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.