- Hydraulics - Pneumatics

- Filter and Separator

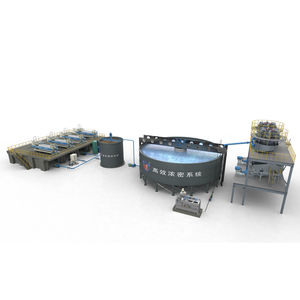

- Frame filter press

- Jingjin Environmental Protection Inc.

Membrane filter press frameautomaticlinear vibrating

Add to favorites

Compare this product

Characteristics

- Type

- membrane, frame

- Operating mode

- automatic, linear vibrating

- Other characteristics

- for sludge treatment

- Applications

- for food products, for chemicals, for pharmaceutical products, for mining applications

- Machine length

5,100 mm

(201 in)- Machine width

1,500 mm

(59 in)- Machine height

1,360 mm

(54 in)

Description

The material of Jingjin frame is Q345B, which tensile strength is 1.4 times of Q235, it makes Jingjin filter press can be operate more safe and stable

The oil cylinder seat, pressing plate and thrust plate are formed by carbon dioxide protection welding

The main beam of Jingjin filter press is designed by adopting welded box construction, and manufactured by making use of submerged arc auto welding technology

All the spare parts that need painted are dealed with high speed centrifugal ball blast descaling and iron scale. After painting MIO epoxy build primer, paint acrylic polyurethane coating directly to make it have the best adhesion. It can save hundreds tons of putty every year, thus not only reduce the cost, but also protect the environment. More important, it improves the adhesion of the paint and antisepsis class of the filter press.

Applicable Industries: - Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other

Showroom Location: - Egypt, Canada, Brazil, Peru, Mexico, Argentina, South Korea

Video outgoing-inspection: - Provided

Machinery Test Report: - Provided

Marketing Type: - Ordinary Product

Warranty of core components: - 1 Year

Core Components: - PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Condition: - New

Automatic Grade: - Automatic

Voltage: - customerized

Power: - Total 9.55kw

Catalogs

No catalogs are available for this product.

See all of Jingjin Environmental Protection Inc.‘s catalogsOther Jingjin Environmental Protection Inc. products

Filter Press

Related Searches

- Filter element

- Filter press

- Automatic filter press

- Liquid filter element

- Sludge filter press

- Plate and frame filter press

- Fiber filter medium

- Chemical filter press

- Sludge treatment filter press

- Filter press for mining applications

- Polypropylene filter element

- Food product filter press

- Pharmaceutical product filter press

- Fiberglass filter medium

- Membrane filter element

- Membrane filter press

- High-pressure filter press

- High-efficiency filter element

- Mobile filter press

- Filter press cloth

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.