- Industrial machines and equipment

- Mixing and Dosing

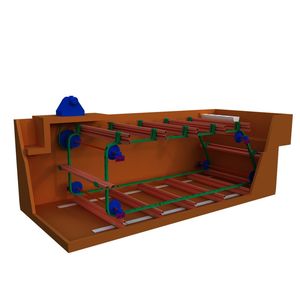

- Paddle mixer

- Jingjin Environmental Protection Inc.

Paddle agitator batchfor liquidsfor the food industry

Add to favorites

Compare this product

Characteristics

- Technology

- paddle

- Batch/continuous

- batch

- Product type

- for liquids

- Applications

- for the food industry, for the chemical industry, water treatment, for the pharmaceutical industry

Description

Agitators are widely used in chemical, pharmaceutical, food, mining, paper, paint, metallurgy, waste water treatment and other industries, suitable for agitating operation with liquid phase as the focus to achieve multiphase mixing including liquid - liquid, liquid -solid, gas – liquid and gas - liquid - solid and heat transfer, mass transfer and chemical reaction. In this agitating test-bed, different trough types have been adopted to match with agitators. Through the observation test of actual flow filed of fluid agitating and data test and collection, we have optimize the design and developed new practical propeller type in order to achieve the best effect of agitating with minimal power consumption under the full conditions. working

Designing process of Jingjin agitator

1. Inputting parameters required for the design.

2. Determining preliminary design

3. Using advanced CFD computational fluid dynamics simulation software to simulate the operation of the design scheme to optimize the design

4. Conducting relevant material mixing tests to verify the design if necessary.

5. Determining the final optimal design

6. Organize the production based on the final design

Catalogs

No catalogs are available for this product.

See all of Jingjin Environmental Protection Inc.‘s catalogsOther Jingjin Environmental Protection Inc. products

Accessory Equipment

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Volumetric dosing unit

- Agitator for the chemical industry

- Liquids dosing unit

- Automatic dosing unit

- Agitator for the pharmaceutical industry

- Paddle blender

- Solid dispensing system

- Powder dosing unit

- Dosing unit for the chemical industry

- Water treatment agitator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.