- Production Machines

- Plastics Processing

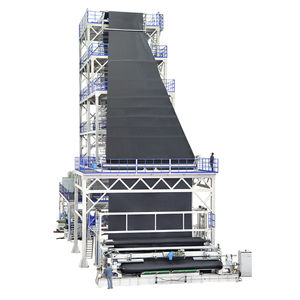

- Blown film coextrusion line

- Jinming Machinery (Guangdong) Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Blown film coextrusion line Classicx 5-layers7-layer6-layer

Add to favorites

Compare this product

Characteristics

- Type

- blown film

- Other characteristics

- 5-layers, 7-layer, 6-layer, 9-layer

- Applications

- barrier film

Description

M5B-1300Q-C

Film Width: 1200 mm

Film Thickness: 0.025~0.12 mm

Max. Output: 250 kg/h

M7B-1700Q-C

Film Width: 1500 mm

Film Thickness: 0.025~0.12 mm

Max. Output: 380 kg/h

M7B-2300Q-C

Film Width: 2100 mm

Film Thickness: 0.025~0.12 mm

Max. Output: 500 kg/h

M7B-2500Q-C

Film Width: 2300 mm

Film Thickness: 0.025~0.12 mm

Max. Output: 650 kg/h

M9B-1300Q-C

Film Width: 1200 mm

Film Thickness: 0.025~0.12 mm

Max. Output: 400 kg/h

M9B-1700Q-C

Film Width: 1500 mm

Film Thickness: 0.025~0.12 mm

Max. Output: 500 kg/h

Since screws and die head of the MBL line are specially designed for processing gas barrier resins such as PA and EVOH, this line is mainly used for producing various specifications of five or more layers film which can meet the demands for gas barrier (O2, N2, CO2…) for the purpose of refreshment, preservation, sealing and shelf life extension.

The whole line is designed in a modular idea that is making it easier for processing different resins, formulas and new products.

Precise layer ratio control system makes it possible to save expensive resin while ensuring the barrier function.

Auto gauge control system equips with closed-loop control system consisting of inline thickness measurement and automatic die head (automatic air ring) for automatic detection of film thickness and control.

The centralized computer control system controls the temperature, rotating speed, pressure, wind speed, haul-off speed, tension and line speed with the digital communication network, displaying and monitoring temperature, pressure, current, voltage, tension, speed, film length and other parameters.

VIDEO

Catalogs

blown film machine catalog

16 Pages

Other Jinming Machinery (Guangdong) Co., Ltd. products

Blown Film Machine Lines

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Multilayer extrusion line

- Extrusion line with water cooling

- Cast-film extrusion line

- Blown film extrusion line

- Coextrusion line

- Multilayer coextrusion line

- Blown film coextrusion line

- Medical packaging extrusion line

- Stretch film extrusion line

- 3-layers coextrusion line

- PE coextrusion line

- 5-layers coextrusion line

- Barrier film coextrusion line

- Cast-film coextrusion line

- CPP extrusion line

- PP coextrusion line

- 7-layer extrusion line

- Food film coextrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.