- Production Machines

- Plastics Processing

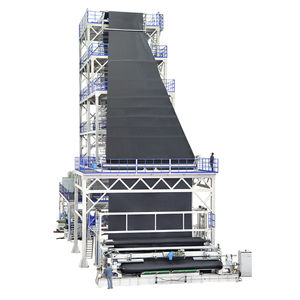

- Blown film coextrusion line

- Jinming Machinery (Guangdong) Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Blown film coextrusion line M2B-1700Q for TPUmultilayerbarrier film

Add to favorites

Compare this product

Characteristics

- Type

- blown film

- Treated material

- for TPU

- Other characteristics

- multilayer

- Applications

- barrier film

Description

M2B-1700Q

Film Width: 1600 mm

Film Thickness: 0.015~0.1 mm(TPU), 0.01~0.03 mm(PE)

Output: 250 kg/h

With the cutting-edge technology and experience in film machinery making, Jinming successful developed a TPU blown film line based on the processing feature and performance of the TPU resin.

Without any impact to the plasticization, rotating speed of the screw is improved by optimizing design of the screw and meanwhile using the smooth barrel. Through trial running, speed of the newly designed barrier screw reaches to 80rpm/min when processing the TPU material. The two-layer spiral screw blown film line adopts central feeding, short channel technique, deducing the retention time of the solution inside the die, and ensuring the speed and the pressure of the solution on the flexible channel are consistent.

The cooling effect of the TPU film and the stability of the film bubble are greatly enhanced and more efficient by using the dual-lip air ring.

The machine line uses gap winder as the TPU film requires low winding tension. The winder is equipped with automatic roll core, and it has the function of auto film cutting, auto change of the film roll, auto unwinding, cutting and winding from both sides, all of which makes it easier to operate the machinery.

The control system is an integrated computer system with bus communication technique supplied by the Austria B&R company.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinming Machinery (Guangdong) Co., Ltd.‘s catalogsOther Jinming Machinery (Guangdong) Co., Ltd. products

Blown Film Machine Lines

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Multilayer extrusion line

- Cast-film extrusion line

- Blown film extrusion line

- Extrusion line with water cooling

- Coextrusion line

- Multilayer coextrusion line

- Blown film coextrusion line

- Medical packaging extrusion line

- Stretch film extrusion line

- 3-layers coextrusion line

- PE coextrusion line

- 5-layers coextrusion line

- Barrier film coextrusion line

- Cast-film coextrusion line

- CPP extrusion line

- PP coextrusion line

- 7-layer extrusion line

- Food film coextrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.