- Metrology - Laboratory

- Metrology and Test Equipment

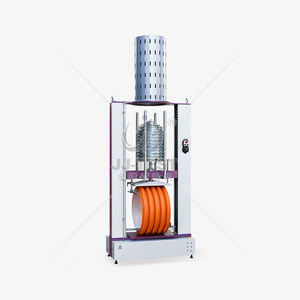

- Thermal cycling tester

- JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Thermal cycling tester JJTCT Seriesfor pipetubethermoplastic pipe

Add to favorites

Compare this product

Characteristics

- Test type

- thermal cycling

- Tested product

- for pipe, tube, thermoplastic pipe

- Applications

- R&D, laboratory

Description

JJTCT Thermal Cycling Tester is applicable to all kinds of plastic pipes, pipe fittings and pipe systems. Under the condition of pressure and different temperatures within the specified time. After completing the test to check the leakage and rupture of pipes and pipe fittings.

Standard

GB/T 33926

GB/T 19993

GB/T 19228.2

GB/T 19228.1

GB/T 18997

GB/T 18993

GB/T 18992

GB/T 18991

GB/T 18742.2

GB/T 18742

ISO 15876

ISO 15875

ISO 15874

ISO 10508

ISO 15877

Features

1.Structural design of semi-pressure system

Frequency conversion pressurization technology applies pressure only at the sample end. The cold and hot water medium tank and front-port pipeline are under normal pressure, which has both safety and long-term stability.

2.Intelligent control of cold and heat exchange

According to the temperature change at the inlet and outlet of the sample. Intelligent control valve opening and orderly exchange. There is no water pouring in the cold and hot water tank;

According to the temperature change, the pressure can be controlled intelligently without pressure impact.

3.Energy saving

Low energy-saving and high-efficiency heat preservation materials;

Exclusively designed noise treatment device. Reduce the noise caused by high-speed water scouring the pipeline;

Created a good laboratory working environment;

Industrial refrigerator + plate staggered stack heat exchanger, refrigeration energy-saving and efficient.

4.High security and reliability

Special high temperature and high pressure stainless steel pump body, corrosion resistance and long service life;

High pressure, fatigue resistant large diameter pneumatic actuator, with long-term stability;

VIDEO

Catalogs

No catalogs are available for this product.

See all of JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd‘s catalogsOther JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd products

Plastic pipe & Pipe fitting valve testing machines

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Test stand

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Compression test machine

- Vertical test machine

- Automatic test stand

- Universal test machine

- Digital measuring device

- Tensile test machine

- Flexure testing machine

- Laboratory test machine

- Industrial testing system

- Precision test machine

- Research and development test machine

- Electromechanical test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.