- Metrology - Laboratory

- Metrology and Test Equipment

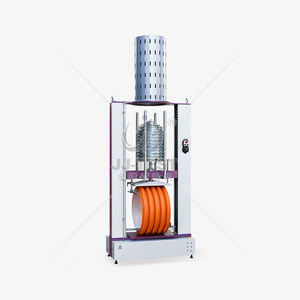

- Crack growth tester

- JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Crack growth tester RCPrapid crack propagationfor pipethermoplastic pipe

Add to favorites

Compare this product

Characteristics

- Test type

- crack growth, rapid crack propagation

- Tested product

- for pipe, thermoplastic pipe, tube

- Applications

- laboratory

Description

RCP is used to determine arrest or propagation of a crack initiated in a thermoplastic pipe intended for the supply of gases or liquids at a specific temperature and internal pressure-Small-scale steady-state test (S4 test).

Standard

GB/T 19280

ISO 13477

Features

RCP Test Frame

1. Rational structure and accurate impact speed. There is energy storage device in basic unit, which shall convert elastic potential energy into kinetic energy, that the impact speed range can be controlled between 1mis and 20m/s.

2. lndustrial control terminal was introduced and colorful touch screen display provides more information to operator, such as sample pre-treatment time, pipe inside current pressure, impact speed, length of crack and test temperature, etc.

3. Fast pressure filling and accurate pressure control. For pipes DN200 to DN500, setting pressure can be arrived within 30s.

4. Thanks to the module design, system can be updated and extended to be suitable for different sizes of pipes.

5. High rigid frame enhance the bearing strength of system and multiple buffers in the frame reduce impact force from the high velocity striker, so that the component connection keep perfect after repeated trials.

6. High-efficiency and reliable energy storage system.Energy storage system with a high storage speed and striker lifting system can be locked firmly or released quickly.

7. The easily adjustable support and the simple assembly & positioning system with quick coupling saves time and has proved to work outstandingly well in operation with samples.

VIDEO

Catalogs

Other JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd products

Plastic pipe & Pipe fitting valve testing machines

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Test stand

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Compression test machine

- Vertical test machine

- Automatic test stand

- Universal test machine

- Digital measuring device

- Tensile test machine

- Flexure testing machine

- Laboratory test machine

- Industrial testing system

- Precision test machine

- Research and development test machine

- Electromechanical test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.