- Machine-tools

- Machining Center

- 3-axis milling machine

- JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

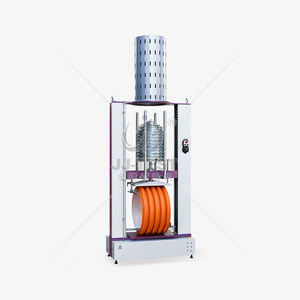

3-axis milling machine JJNMMverticalfor PVCautomatic

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Machined material

- for PVC

- Other characteristics

- automatic

- Associated function

- cutting, notching, grooving, chamfering

Description

This instrument is an equipment for sample incision processing for the test method of resistance to slow crack growth and slow growth of thermoplastic pipes for fluid transportation. The instrument has a high degree of automation, precise cutting precision, and humanized design, which is convenient for safe use by operators.

Standard

GB/T 18476

ISO 13479

Features

1. It adopts industrial PLC automatic control, hoisting a movable and rotating large-size full-color touch screen operation display terminal.

2. Modular design structure, the notch grooving tool is located directly above the test tube, and it is easy to observe and operate when milling the notch.

3. The servo system is used to control the speed and feed rate of the tool to ensure the cutting speed required by the standard.

4. The pipe and the slotting machine should be fixed by mandrel hoisting and clamping, with the tool parallel to the inner wall of the pipe;

It is necessary to ensure that the depth of the milling groove is not limited by the ellipse of the pipe and the difference in wall thickness, and to ensure that the depth of the cut is consistent.

5. X and Y feeds adopt high-precision linear linear guides and high-precision ground ball screws, which have high cutting precision and ensure the validity of the test data for slow crack growth resistance.

6. The high-precision 60o V-shaped carbide cutter ensures that the end surface of the pipe is smooth and clean after cutting.

Catalogs

No catalogs are available for this product.

See all of JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd‘s catalogsOther JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd products

Plastic pipe & Pipe fitting valve testing machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.