- Metrology - Laboratory

- Metrology and Test Equipment

- Impact tester

- JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd

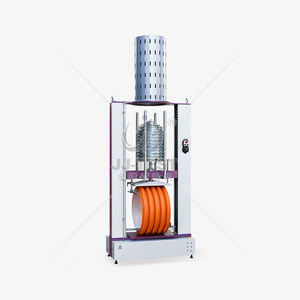

Falling weight impact tester JJFWI-323for pipesUSB

Add to favorites

Compare this product

Characteristics

- Test type

- falling weight impact

- Tested product

- for pipes

- Other characteristics

- USB

Description

It is used to test the impact resistance of pipes, pipe fittings, plates, profiles and other plastic products. The equipment adopts the mechanical energy storage impact method, which can simulate the free fall impact test at a height of 20 meters, is equipped with a speed measuring device, and the impact speed (5-20) m/s can be set arbitrarily.

Features

1. Using servo motor to drive the ball screw to accumulate energy to the spring and provide a set high-speed impact;

2. The accuracy of impact speed is within ±1m/s;

3. The impact height can be set arbitrarily within a simulated 20m height range;

4. The combined V-shaped shim design makes it suitable for pipes of different pipe diameters and plate samples of different thicknesses;

5. V-shaped iron is automatically raised and lowered, and the sample is in place to detect the function;

6. Twin screw support, stable support, good rigidity, and the test state is closer to the actual use of the pipe;

7. The large touch screen man-machine interface provides users with detailed test information, automatically records the height of each impact, impact weight, impact velocity, measured impact velocity and theoretical impact velocity ratio, and prompts the user to enter the sample after impact Whether it is broken ;

8. The dual-output design of micro-printer and USB disk provides more options for communication and storage of test data;

9. Built-in speed measuring device, which can accurately measure the impact velocity of each falling hammer and realize the simulated impact height;

10. Power-down data protection, incoming call data recovery.

Catalogs

No catalogs are available for this product.

See all of JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd‘s catalogsOther JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd products

Plastic pipe & Pipe fitting valve testing machines

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Test stand

- Material testing machine

- Temperature test cabinet

- Automatic test machine

- PC-controllable testing machine

- Compression test machine

- Vertical test machine

- Automatic test stand

- Universal test machine

- Digital measuring device

- Tensile test machine

- Flexure testing machine

- Industrial testing system

- Laboratory test machine

- Precision test machine

- Research and development test machine

- Electromechanical test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.