- Machine-tools

- Machine Tool Accessory

- Rectangular base plate

- Johann Fischer Aschaffenburg

- Products

- Catalogs

- News & Trends

- Exhibitions

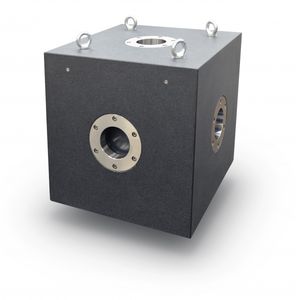

Rectangular base plate

Add to favorites

Compare this product

Characteristics

- Configuration

- rectangular

Description

Precise base for transacting measuring and inspection tasks in production shops and inspection rooms

Each JFA surface plate is made by JFA. JFA does not offer trade goods of foreign origins.

JFA selects and purchases its hardstone material. JFA surface plates are worked and lapped in our production shop as well as in our clima-controlled inspection areas. JFA's technicians calibrate the achieved accuracies. JFA surface plates are quality products. The experience of our technicians grant for JFA's high quality standard.

JFA meets high approval in production of surface plates in XL and XXL-sizes. e.g. dimension 4.000 x 3.000 mm

Material

The base material for JFA surface plates is black natural hardstone - Gabbro Impala. This material has best suited technical properties. JFA surface plates are natural finish and not treated with chemicals. They are neither painted, nor waxed respectively oiled.

Working

The measuring surface - top side - is mechanically and manually fine and wear-resistant worked. Flatness of the measuring surface according to DIN 876 or JFA standard. The outer faces are finely, the bottom face is diamond-worked. Edges are chamfered for protection against damages. With steel ball inserts at the bottom face. Precise longitudinal outer faces as requested.

Calibration certificate

A calibration certificate is part of scope of delivery. The measuring results are retraceable to National standards. Factory- or DAkkS calibration certificate can be issued on request.

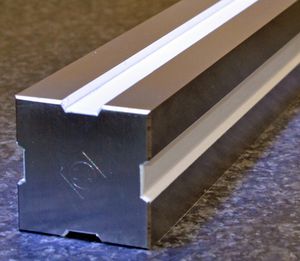

Accessories for statically defined setting up of surface plates

JFA accessories for the setting up of surface plates are equipped with screws with fine thread M27.

Other Johann Fischer Aschaffenburg products

Measuring Tools

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.