- Metrology - Laboratory

- Metrology and Test Equipment

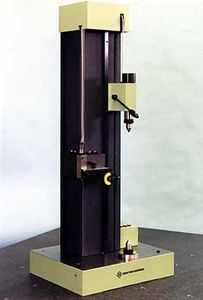

- Concentricity testing device

- Johann Fischer Aschaffenburg

- Products

- Catalogs

- News & Trends

- Exhibitions

Concentricity testing device manualbenchtopprecision

Add to favorites

Compare this product

Characteristics

- Test type

- concentricity

- Operating mode

- manual

- Configuration

- benchtop

- Other characteristics

- precision

Description

Micron-precise holding and measuring of large rotationally symmetrical workpieces – centreless and between centres

Superstructure / Functionality

The base of the superstructure is formed by a base plate made of natural hardstone. Two flat and parallel T-guiding and -clamping slots made of steel are brought into the finely ground and lapped top side in longitudinal direction.

A pair of gauge block roller boogies is used for the defined centerless bearing of the workpieces to be measured. The roller boogies are adjusted by means of the gauge blocks so that the nominal axis height of the workpieces to be measured does not change - regardless of the workpieces‘ bearing diameter. Equipped with steel tongue-and-groove springs and a air-beared transport system in the base, the roller boogies are moved and positioned by hand in a wear-resistant and user-friendly manner. To avoid an axial displacement of the workpieces to be measured due to rotation, two axial stops, designed as stable steel/welded construction, are provided as counter holders.

A pair of tailstocks with base bodies made of special cast iron as well as quills and grooved springs made of hardened steel serve for the defined bearing of the workpieces to be measured between centers. The workpieces to be measured are clamped by manual adjustment of one tailstock quill via handwheel. Like the gauge block roller boogies, the tailstocks are also moved and positioned with an air-beared transport system.

An exemplary instrument for carrying out measuring tasks is a measuring stand with adjustable column and fine adjustment, to whose measuring arm a dial gauge or fine indicator is attached.

Other Johann Fischer Aschaffenburg products

Tailor-made Measurement Systems

Related Searches

- Measuring device

- Measuring machine

- Automatic measuring machine

- Manual test kit

- High-precision measuring machine

- Industrial test equipment

- Automatic measuring device

- Benchtop measuring device

- Distance measuring machine

- Control measuring machine

- Laboratory measuring device

- High-precision measuring device

- Geometry measuring device

- Tabletop testing device

- Electronic measuring device

- Concentricity measuring instrument

- Length measuring device

- Precision test equipment

- Calibration measuring device

- Manual measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.