- Metrology - Laboratory

- Metrology and Test Equipment

- Concentricity measuring system

- Johann Fischer Aschaffenburg

- Products

- Catalogs

- News & Trends

- Exhibitions

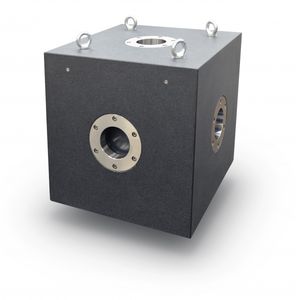

Concentricity measuring system gaugetubeshaft

Add to favorites

Compare this product

Characteristics

- Measured physical value

- concentricity

- Technology

- gauge

- Measured material

- tube, shaft, bearing

- Other characteristics

- high-precision

Description

Adjustable for different bearing diameters with use of gauges.

For high precision concentricity measurements of rotationally symmetrical parts such as shafts, rollers, and tubes. The construction of the JFA precision roller blocks is designed to accommodate very heavy workpieces. These precision instruments can also be used in combination with a tailstock pair or spindle head with counter tailstock.

Construction - rigid roller support structure

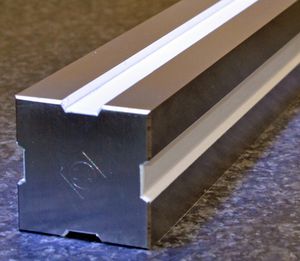

The main body is made of cast iron or steel. The roller carriers are made of steel. Running precision of high-precision rolling beared rolls up to 0,002 mm. With finely honed t-nuts of hardened steel. The precision roller blocks are adjustable with gauges. They can be positioned and clamped in T-guiding and clamping grooves of eg. surface plates.

Construction - floating roller support structure

The roller support structure is perpendicular to the workpiece axis Floating. The rest of execution as described above. These precision roller blocks will be used, if the length and weight of the workpieces demand the support of more than two bearings. That allows the workpieces in the rotation to 0 - 360 ° to follow the concentricity of the bearings towards the side. Faults of concentricity become measurable. The deflection of the workpiece is eliminated.

Adjustment of the bearing diameter with final dimensions

The roller steadies can be pre-adjusted in accordance to known diameters with the help of gauge blocks, so that workpieces with different outside diameters can also be aligned high precisely as well as equal to the ideal axis.

Other Johann Fischer Aschaffenburg products

Measuring Tools

Related Searches

- Measuring device

- Measuring machine

- Automatic measuring machine

- Manual test kit

- High-precision measuring machine

- Industrial test equipment

- Automatic measuring device

- Benchtop measuring device

- Distance measuring machine

- Control measuring machine

- Laboratory measuring device

- High-precision measuring device

- Geometry measuring device

- Tabletop testing device

- Electronic measuring device

- Concentricity measuring instrument

- Length measuring device

- Precision test equipment

- Calibration measuring device

- Manual measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.