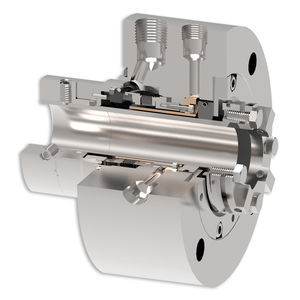

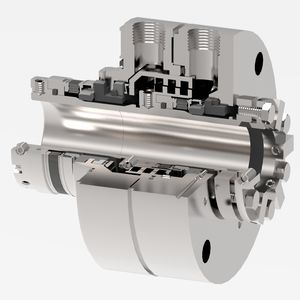

Bellows mechanical seal 285cartridgespringfor shafts

Add to favorites

Compare this product

Characteristics

- Type

- cartridge, spring, bellows

- Applications

- for cryogenic pumps, for shafts

- Material

- stainless steel, carbon

- Other characteristics

- face, gas-lubricated

- Operating pressure

Max.: 7 bar

(102 psi)Min.: 0 bar

(0 psi)

Description

Gas-lubricated, Non-contacting Single Seal For Cryogenic Pumps

Unique Spiral Groove Technology

As the worldwide leader in spiral groove technology, John Crane is the first to utilize non-contacting seals in cryogenic applications. The Type 285 can safely seal the most common industrial liquid gasses, such as liquid nitrogen, oxygen, argon and carbon dioxide. It fits the most popular cryogenic pumps — site-based and road tanker pumps — and meets liquid oxygen (LOX) safety standards. The John Crane spiral grooves enable the seal to operate on a gas film by gathering and compressing the vaporized liquid. As the gas is forced towards the closed groove ends, the pressure rises, which creates a cushion to separate the sealing faces. Since the seal faces do not contact, dry-running and face wear problems, which are associated with conventional contacting seals, are virtually eliminated.

Features

California Residents: PROPOSITION 65 WARNING

Specially designed stationary edge-welded metal bellows.

Available in flanged, right- and left-hand threaded designs or as a cartridge.

Meets liquid oxygen (LOX) safety standards.

Anti-spark sleeve and retaining ring.

Reduced power consumption with minimal product loss. Since the seal faces do not contact, dry-running and face wear problems, which are associated with conventional contacting seals, are virtually eliminated.

The design and materials of construction meet the industry safety requirements, allowing the Type 285 to seal all of the common industrial liquid gasses including oxygen, nitrogen and argon.

The Type 285 is more tolerant to system upsets and increases your mean time between pump maintenance.

Catalogs

Related Searches

- Mechanical seal

- O-ring gasket

- Circular gasket

- Lip seal

- Pump mechanical seal

- Metal seal

- Metal mechanical seal

- Flat gasket

- Spring mechanical seal

- Gasket sheet

- Cartridge mechanical seal

- Shafts seal

- Balanced mechanical seal

- Mechanical seal for the chemical industry

- Stainless steel gasket

- Braided PTFE packing

- Composite mechanical seal

- Face mechanical seal

- Carbon mechanical seal

- Bellows mechanical seal

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.