- Packing - Handling - Logistics

- Packing and Packaging

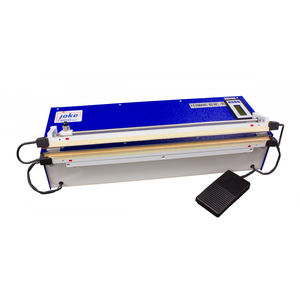

- Manual impulse sealer

- joke Folienschweißtechnik GmbH

Manual impulse sealer FERMANT® N serieshorizontalsachetbag

Add to favorites

Compare this product

Characteristics

- Operating mode

- manual

- Orientation

- horizontal

- Product applications

- sachet, bag, for film

- Product applications

- for pharmaceutical products, for the food industry

- Other characteristics

- table-top

- Weld length

220 mm, 400 mm, 600 mm, 800 mm, 1,200 mm

(8.66 in, 15.75 in, 23.62 in, 31.5 in, 47.24 in)- Weld width

4 mm

(0.16 in)

Description

Some can do it beautifully, some cheaply, all can process PE films, but we can do more! The FERMANT® series offers versatile problem-solving options for virtually all thermoplastically sealable materials such as for example PE up to 2 x 400 µm, compound films, fabrics, fleece, textiles, foams, insulating materials, filter materials, medical packaging, some PVC films, acrylic materials and films, PET films and tubes.

In-house heater strip production means that almost nothing remains to be desired, whether flat heater strips, cutting wires, beaded heater strips, T-profiles, double-seam, sealing strips and zebra heater strips are involved, even in all lengths and widths.

Accompanying this wide range of possible variations, we offer the selection of digital device controllers, temperature controllers, stainless steel housings, different sealing bar variants such as for example water-cooled bars and the option of building up a higher sealing pressure if necessary.

The advantages at a glance:

• Devices in the dimensions 22, 40, 60, 80 and 120 cm sealing length

• Widest array of heater strips possible

• Constant contact pressure

• Film passage is identical to the sealing seam length

• Infinite sealing parameter adjustment

• Reproducibility of the sealing parameters governed by a digital controller

• Integrated item counter

• Operation using an electric foot switch; the operator keeps both hands free!

• Can be operated as a tabletop sealing device or on the machine stand

Applications:

• bags, films and sacks

• thin foams, fleeces and fabrics

• mechanical and electronic components

• foods

• bulk goods

• pharmaceutical items

• tab labels

• production of advertising media

Catalogs

joke-catalogue

72 Pages

Other joke Folienschweißtechnik GmbH products

Film sealing devices

Related Searches

- Sealer

- Heat sealer

- Impulse sealer

- Automated sealing machine

- Manual impulse sealer

- Plastic bag

- Horizontal impulse sealer

- Bag sealer

- Handheld heat sealer

- Bag impulse sealer

- Sachet impulse sealer

- Film impulse sealer

- Table-top impulse sealer

- Pedal-operated impulse sealer

- Impulse sealer for the food industry

- Film heat sealer

- Film sealing machine

- Pharmaceutical product impulse sealer

- Vertical impulse sealer

- Cosmetic product sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.