- Packing - Handling - Logistics

- Packing and Packaging

- Automatic sealing machine

- joke Folienschweißtechnik GmbH

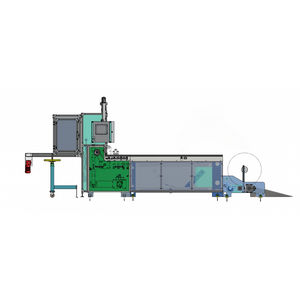

Automatic sealing machine PLD/Sbagsausageedge

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Product applications

- bag, sausage, edge, for cosmetic products, for poultry, meat

- Domain

- for the food industry

- Other characteristics

- modular

Description

We at joke have developed a versatile modular solution for special requirements in terms of hygiene and shelf-life: the PLD/S Modular bag unit. Owing to the variable design, sealed-edge or shrink bags can be manufactured in different sizes, zips and the like can be incorporated -perfectly tailored to the respective needs and using the appropriate films.

A jack-of-all-trades and all-rounder

Sealed-edge bag, shrink bag, round bottom or stand-up, with a zipper or adhesion closure and special sealing geometries – the PLD/S automatic bag machine is an all-rounder.

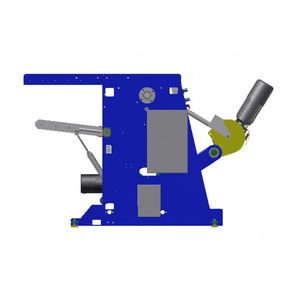

Owing to the modular design, it fits precisely into theproduction line. The modules – all in standardised di-mensions – are available for different processing stages:unwinding, bottom fold, film width edge control, variou different crossways, lengthways and spot sealingstations, knifes and Euro hole punching in addition to other elements can be combined. The unit processes flat films, tubular and semi-tubul, paper and aluminium compounds in addition to sealable PA/PE films up to athickness of 400 µm and working widths of 600/900/1,200 mm.

The all-rounder will be profitably used above all in thefood industry and the cosmetic sector. Sausage, meat or poultry individually packed in shrink film bags are now a„must“ in food markets.

High quality components

Servomotors are used for high processing quality, which power the unwinding mechanism in addition to all sealing stations and crossways knives. A photoelectric cell for printed films is incorporated as standard. The sealed seam sealing unit is operated using a touchscreen display. Various parameters can be saved using the integrated format memory.

VIDEO

Catalogs

No catalogs are available for this product.

See all of joke Folienschweißtechnik GmbH‘s catalogsOther joke Folienschweißtechnik GmbH products

Machines

Related Searches

- Sealer

- Heat sealer

- Impulse sealer

- Automated sealing machine

- Manual impulse sealer

- Plastic bag

- Horizontal impulse sealer

- Handheld heat sealer

- Bag sealer

- Sachet impulse sealer

- Bag impulse sealer

- Film impulse sealer

- Table-top impulse sealer

- Impulse sealer for the food industry

- Pedal-operated impulse sealer

- Film heat sealer

- Film sealing machine

- Pharmaceutical product impulse sealer

- Vertical impulse sealer

- Impulse sealer for laboratory applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.