- Production Machines

- Other Manufacturing Equipment

- Plastic bag making machine

- joke Folienschweißtechnik GmbH

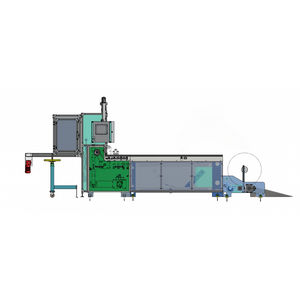

Plastic bag making machine OS10025automatic

Add to favorites

Compare this product

Characteristics

- Material

- plastic

- Other caracteristics

- automatic

Description

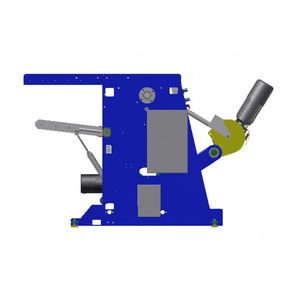

Machine for manufacturing security bags made of suitable polyethylene film (LD-PE, LLD-PE, HD-PE, mixed or industrial film) in addition to security carrier bags for duty-free shops. This machine can be equipped with 7 to 11 servo drives. As an option, this machine can be equipped with motor-driven and automatic device tracking system. The film is always guided to the next desired printing mark in this case, thereby minimising production rejects and scrap. 2 forward-feed servo drives, 1 servo drive for cutting or sealing system, 3 - 6 servo drives for the additional devices and 2 servo drives for the storage system. Furthermore, all film takeoffs are equipped with the latest CFK takeoff roller technology from joke renotec.

This system is assembled to suit individually the respective customer requirements.

The advantages at a glance:

• Simple touchscreen operator guidance

• Formula management (i.e. your individual settings for previous machine orders are saved)

• Pre-positioning of the additional devices when configuring a new order

• With or without autotracking of the additional devices to the printing mark for optimisation of the pressure for sealing and for cutting

• Various different security tapes can be used in the field of continuous and intermittent orders

• Guillotine cutting system and/or sealing and cutting system

• Energy saving by a very low moment of inertia in all takeoff drives combined with the latest CFK roller technology

• Reduction in shutdown periods owing to rapid threading in of the film webs

• Very good accessibility for cleaning, maintenance and service, in addition to short set-up times

Catalogs

No catalogs are available for this product.

See all of joke Folienschweißtechnik GmbH‘s catalogsOther joke Folienschweißtechnik GmbH products

Machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.