- Metrology - Laboratory

- Laboratory Equipment

- Liquid filter

- JOMESA Meßsysteme

- Products

- Catalogs

- News & Trends

- Exhibitions

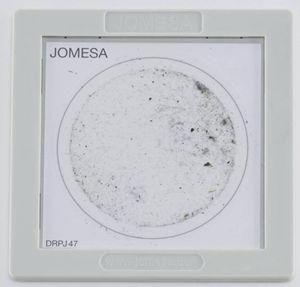

Membrane filter liquidpolyamidenylon

Add to favorites

Compare this product

Characteristics

- Designed for

- liquid

- Filtration element

- membrane

- Material

- nylon, polyamide, cellulose fiber, PET

- Cleaning

- self-cleaning

- Operating pressure

Max.: 800 bar

(11,603.019 psi)Min.: 0 bar

(0 psi)- Filtration size

Max.: 20 µm

Min.: 0.8 µm

Description

•Cleanliness

Orignally filters were produced for filtration,so cleanliness of the membrane itself was no issue, and filter manufacturer did not care for remaining particles on filter membranes.

ISO 16232 and VDA Vol.19 give clear instructions about the blank value, which is the limit of contaminaion of the cleanliness analysis equipment itself. Filters are of course part of the analysis equipment and thus contribute to the blank value.

In cleanliness analysis, filter cleanliness is of importance and should be specified.

JOMESA met this challenge since 2015 by cleaning, lasercutting and packing the filters in a cleanroom class 7 (ISO 14644).

JOMESA controls cleanliness of filter production with a dedicated optical (JOMESA HFD) and SEM (JOMESA PSE) systems.

•Porosity

SEM images of typical filter membranes

Open mesh filters (> 15µm poresize) can be easily measured by image analysis.They can be used to separate different particle sizes:

Mesh filters with 20µm holes (pores) size mesh will allow all particles smaller than 20µm to pass and hold back all particles larger.

Related Searches

- Liquid separator filter

- Microscope

- Inspection microscope

- Easy cleaning pre-filter

- Self-backwashing filter

- Stereo microscope

- Optical stereo microscope

- Capsule filter

- Zoom stereo microscope

- Membrane filter

- Laboratory stereo microscope

- Inspection stereo microscope

- Industrial stereo microscope

- Nylon filter

- Materials inspection microscope

- Analysis stereo microscope

- Medical stereo microscope

- Polyamide filter

- X-ray microscope

- Cellulose fiber filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.