- Packing - Handling - Logistics

- Packing and Packaging

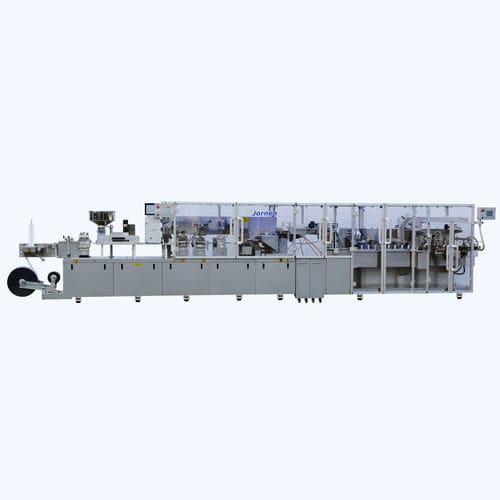

- Packaging line for the pharmaceutical industry

- Jornen Machinery Co., Ltd.

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

Packaging line for the pharmaceutical industry BPL120for pharmaceutical productssyringefor cosmetic products

Add to favorites

Compare this product

Characteristics

- Application domain

- for the pharmaceutical industry

- Product applications

- for pharmaceutical products, syringe, for cosmetic products, for medical applications, for bottles, flexible packaging

- Other characteristics

- fully-automatic, blister, with automatic feeder

Description

This Blister-Cartoner Line is combined with the DPP260Ki2 Blister Machine and ZH120i Cartoner.

Through the integration of a blister and cartoner module for packaging and cartoning of pharmaceutical tablets, capsules, and ampoules, this Blister Packaging Line is Jornen’s innovative response to the need for high efficiency and low-cost operation, flexibility, and maximum productivity for small and medium batch production.

·Processes all common solid dose products and all types of forming material.

·The machine can achieve 180 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and waste material trimming cutter (optional).

·Capable of all standard types of closure systems for cartons from tuck-in to hot-melt.

·The heart of a Blister Line is the connection between the Blister Machine and Cartoner. In this line, the connection phase is truly innovative thanks to two vacuum arms and the blister counting magazine that adopt precise servo technology. These accurately control blister transfer, faulty blister rejection, positioning, and feeding, etc., to assure the stability of high running speed.

·Since this Line adopts a transfer belt to connect the Blister Machine and Cartoner, it provides easy changeover for different sizes of formats and cartons.

·This line adopts the fully-enclosed structure and safety door, it is in line with the stringent safety standards.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jornen Machinery Co., Ltd.‘s catalogsOther Jornen Machinery Co., Ltd. products

Blister packaging line

Related Searches

- Jornen packaging machine

- Automatic filler

- Jornen automatic packaging machine

- Liquid filler

- Filler for the food industry

- Jornen packaging machine for the food industry

- Bottle filler

- Food product filling machine

- Semi-automatic filler

- Film packing machine

- Jornen bell type packaging machine

- Filling system for the chemical industry

- Jornen filling machine for the pharmaceutical industry

- Jornen packaging line

- Filler for the cosmetics industry

- Bag packing machine

- Jornen medical packaging machine

- Thermoformer

- Checkweigher

- Automated thermoforming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.