aluminum/plastic/aluminum blister pack.

This type of Blister Machine adds one tropical aluminum forming station and a second sealing station to allow the plastic thermoforming blister package to be sealed with formed tropical aluminum again.

Because the item is filled in thermoforming pocket or cavity so it can adopt universal feeder, it is low cost and ease of operation.

The inspecting camera can detect the fault blister card easly because of the transparence of thermoforming plastic.

The tropical aluminum has same property as cold forming aluminum that can offers a nearly complete barrier for water, light and oxygen, perfectly protect the medicine.

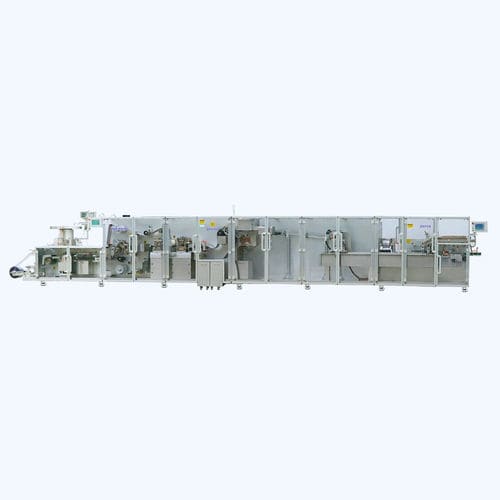

The characteristics of Blister Packaging Line

> The alu/pvc unit adopts larger forming area stating and rotary style sealing stating thus increase the speed.

> The tropical alu forming station has larger forming area archive larger output requirement.

> The second sealing station has larger sealing area to allow the plastic thermoforming blister package to be sealed with formed tropical alu at higher output capacity.

> The punch station can adopts the crossing type, the trimming waste is about 1mm between two blisters; it can save more material.

> Thanks to rotary sealing style (alu-pvc) and larger tropical aluminum forming and sealing area, the machine archives high output, for the size of 98mm*70mm, the output can up to 180 blister cards/minute (DPH260H3) and 270 blister cards/minutes (DPH350H3).

> The Caroning Machine is intermittent style but thanks to its rotary cartons pick-up device and continuous motion blister conveyor chain, the machine can runs at higher speed than traditional cartoning machine.