- Packing - Handling - Logistics

- Packing and Packaging

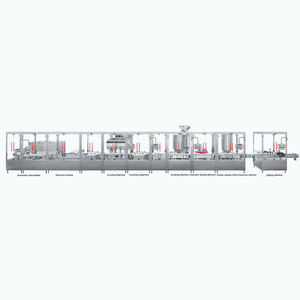

- Fully-automatic bottling and packaging line

- Jornen Machinery Co., Ltd.

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

Fully-automatic bottling and packaging line sustainable

Add to favorites

Compare this product

Characteristics

- Options

- fully-automatic, sustainable

Description

● This compact counting line adopts an integrated and modular design, including Unscrambler+Counting+Double Validation Function for Counting and Filling System+Capping+Sealing Machine. The total length of the line is less than 6 meters, which is reduced by half compared to ordinary counting lines. It can help enterprises save about 50% of equipment space and is suitable for upgrading and renovating old workshop production lines.

● The entire system, including each equipment unit, can be separated for convenient transportation and installation.

Adopting a tooth-shaped synchronous bottle-moving system smooths the entire process without shaking, impacting, or overturning. The tooth-shaped synchronous bottle-moving system, bottle specifications, and the number of drugs filled in the bottle all have formula storage functions, which can be called up with one click when changing specifications and are intelligent and efficient.

● The compact counting line adopts CCD intelligent visual counting and double validation function for the counting and filing system to control the unqualified counting rate within 1/50000.

● The CCD intelligent vision system has an automatic fill light adjustment function and strong dust prevention ability; even for tablets with large dust, it can ensure counting accuracy. Realized the precise counting for a long time in a strong dust environment.

● It adopts a claw-type torque control capping system, suitable for various bottle caps, such as CRC pressure capping, gold-plated caps, and anti-theft safety caps. This system ensures the bottle cap is tightened without damaging the cap and body

● Optional isolator can realize the packaging of anti-tumor drugs

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jornen Machinery Co., Ltd.‘s catalogsOther Jornen Machinery Co., Ltd. products

Solid Dose Bottle Packaging Machines

Related Searches

- Jornen packaging machine

- Automatic filler

- Jornen automatic packaging machine

- Liquid filler

- Filler for the food industry

- Jornen packaging machine for the food industry

- Bottle filler

- Food product filling machine

- Semi-automatic filler

- Film packing machine

- Jornen bell type packaging machine

- Filling system for the chemical industry

- Jornen filling machine for the pharmaceutical industry

- Jornen packaging line

- Filler for the cosmetics industry

- Bag packing machine

- Jornen medical packaging machine

- Thermoformer

- Checkweigher

- Automated thermoforming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.