- Industrial machines and equipment

- Welding and Assembly

- Automatic assembly machine

- JR Automation - A Hitachi Group Company

Automatic installation machine SmartAttach®semi-automaticfor industrial applicationscustom

Add to favorites

Compare this product

Characteristics

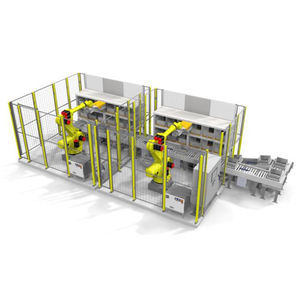

- Operational mode

- semi-automatic, automatic

- Applications

- for industrial applications

- Other characteristics

- pneumatic, compact, custom, modular, precision

Description

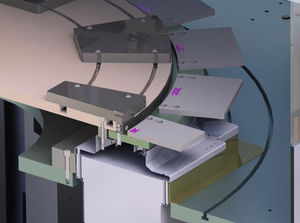

The average airplane utilizes 25,000 nutplates – all installed by hand. The patent-pending SmartAttach® Automated Nutplate Installation System eliminates the need for manual alignments, multiple tools, and procedures required by conventional nutplate attachment methods. The SmartAttach® Automated Nutplate Installation System integrates centering, drilling, lubrication, countersinking, and riveting operations in a single machine. You can cut nutplate attachment times by at least 60%. You’ll greatly improve precision and repeatability for rivet and center holes. It also brings you IoT capabilities for intelligent monitoring and process management.

Ramp Up Your Riveting

If you’re ready to dramatically accelerate production, it’s time to get on board.

Save Time

SmartAttach® Automated Nutplate Installation System safely installs nutplates up to 9 times faster than manual labor

Gain Efficiency

With no need for health benefits or vacation days, our automated solution performs the work of up to 10 dedicated workers

Maximize Floorspace

Requiring far less floorspace, our automated technology dramatically reduces your manufacturing footprint

Ensure Quality

SmartAttach® Automated Nutplate Installation System's laser-focused precision drastically reduces the potential for human error

Monitor Performance

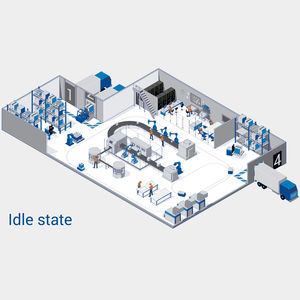

Integrated IoT technology tracks usage, productivity, and even predicts maintenance needs

MEET YOUR NEWEST CREW MEMBER

Occupying a mere 74 square feet of floor space, SmartAttach® Automated Nutplate Installation System utilizes up to two operators to drill and rivet nutplates to exacting standards at a pace never before possible…up to 9 times faster than manual teams alone.

VIDEO

Catalogs

SmartAttach®

3 Pages

Other JR Automation - A Hitachi Group Company products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.