- Packing - Handling - Logistics

- Handling and Lifting

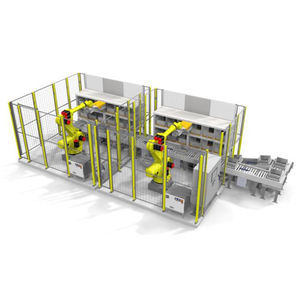

- Automatic handling equipment

- JR Automation - A Hitachi Group Company

Automatic handling equipment integrated

Add to favorites

Compare this product

Characteristics

- Options

- automatic, integrated

Description

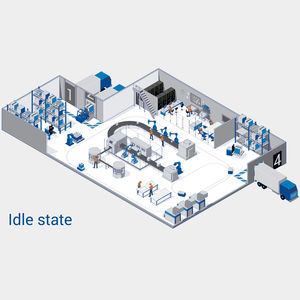

Material handling automation uses advanced technology to move parts or products where you need them, when you need them. Automated material handling looks for opportunities to integrate robotics or other technology into your facility, line, or system to ensure that all integration is efficient, safe, and ergonomic.

Benefits of material handling automation for your business

Automation positively impacts your business in several ways. Our customers have been able to increase efficiency and reliability throughout their manufacturing, shipping, and delivery processes—making their employees and their customers happier. By implementing automation in critical areas, our customers have been able to improve:

Examples of material handling automation in action

Material handling automation can drastically increase uptime. Relying on manual work can be slow, inconsistent, and even dangerous. Material handling robots, conveyors, and feeders can work simultaneously with consistency and flexibility. Our customers achieve excellent results with automated systems in their material handling processes.

Reliability and consistency

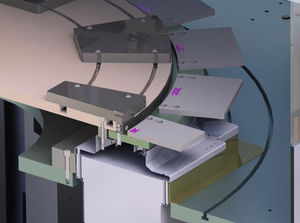

Our solutions can move parts carefully and quickly while reducing errors. Material handling automated systems can include sensors, robotics, conveyance, feeding systems, and other material handling technologies to meet production needs. One of our medical customers manufactures bottles of patented liquid throughout its facility in stages. The company’s preexisting system relied on operators, but it had higher failure and damage rates. The new system carried, rotated, and conveyed the bottles without splashing the liquid.

Catalogs

No catalogs are available for this product.

See all of JR Automation - A Hitachi Group Company‘s catalogsOther JR Automation - A Hitachi Group Company products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.