- Robotics - Automation - Industrial IT

- Automation

- Production automation system

- JR Automation - A Hitachi Group Company

Production automation system process

Add to favorites

Compare this product

Characteristics

- Options

- process, for production

Description

JR Automation has a proven track record in engineering solutions to fit your plastic material and products.

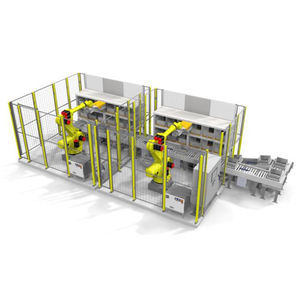

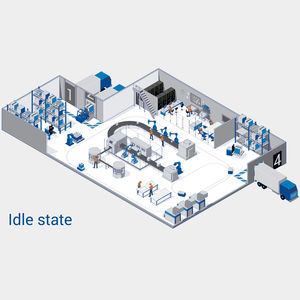

Plastic processing automation uses robotics, vision, and other advanced technology to complete tasks such as plastic welding, heat staking, marking, riveting, spin welding, injection molding machine tending, or other processes involving plastic parts. Using automation for these tasks improves speed, precision, repeatability, and safety. Manufacturers can automate a single process or multiple processing tasks. For example, JR Automation integrates robotics, vision, and conveyance systems to complete multiple plastic processing tasks within a single work cell or a complex production line.

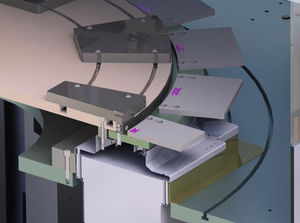

Many manufacturing processes involve plastic, from etching bar codes into plastic parts for traceability to welding parts together. Heat staking is a popular alternative to assembling parts with screws or adhesives, and it's easier to automate. Plastic welding involves heat and precision to avoid warping or damaging components. There are several welding applications a company can use to accomplish the joining of plastic parts, including:

• Heat staking

• Friction welding

• High-frequency vibration welding

• Laser welding

Catalogs

No catalogs are available for this product.

See all of JR Automation - A Hitachi Group Company‘s catalogsOther JR Automation - A Hitachi Group Company products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.