- Production Machines

- Plastics Processing

- Compounding extruder

- JSW The Japan Steel Works, Ltd.

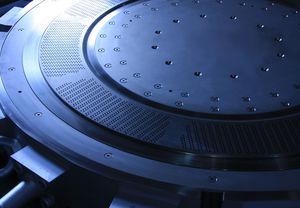

Compounding extruder CMP seriestwin-screwwith underwater pelletizing

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Number of screws

- twin-screw

- Other characteristics

- with underwater pelletizing

- Output

Min.: 0.5 t/h

(0.3062 lb/s)Max.: 100 t/h

(61.2395 lb/s)- Screw diameter

Min.: 69 mm

(2.7 in)Max.: 443 mm

(17.4 in)

Description

We deal with medium & large sized blow molding machine for PFT (plastic fuel tank for automobile and motorcycle) , spoiler for automobile, container etc.

We have a variety of delivery results and get a high evaluation in response to the demand of the customers.

Overview

Overview of the blow molding machine

Blow molding is a molding method in which a resin called a parison, which is a pipe made of a molten thermoplastic resin, is blown out and blown out to take out after cooling.Conventionally, it was used to manufacture bottle containers for eye drops, medicines, cosmetics, foods, detergents, etc. Recently, its features such as cost performance, high rigidity and light weight have been evaluated, and various types of products, mainly automobile parts, have been evaluated. Application fields are also expanding to industrial parts.

Main Component I: Exturder

In order to obtain a good-quality molded product, a good parison must first be formed. The most important factor affecting this is the extruder.

The main components are a cylinder, screw, hopper, speed reducer, drive motor, and heating / cooling section.

Catalogs

No catalogs are available for this product.

See all of JSW The Japan Steel Works, Ltd.‘s catalogsOther JSW The Japan Steel Works, Ltd. products

Polyolefin Pelletizing Extruder

Related Searches

- Screw extruder

- Twin-screw screw extruder

- Single-screw screw extruder

- Compounding screw extruder

- Compact screw extruder

- Laboratory screw extruder

- Masterbatch screw extruder

- Pelletizing screw extruder

- Stretch film making machine

- High-throughput screw extruder

- Flexible screw extruder

- EVA extruder

- Extruder with underwater pelletizing

- LDPE screw extruder

- Hot-melt screw extruder

- Pharmaceutical screw extruder

- Cable extruder

- Vented extruder

- Extrusion barrel

- Extrusion screw

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.