- Production Machines

- Plastics Processing

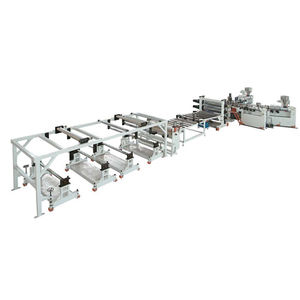

- 3-layers coextrusion line

- Jwell Extrusion Machinery Co., Ltd., Shanghai

Pipe coextrusion line JWG seriesfor PVC3-layers

Add to favorites

Compare this product

Characteristics

- Type

- for pipes

- Treated material

- for PVC

- Other characteristics

- 3-layers

Description

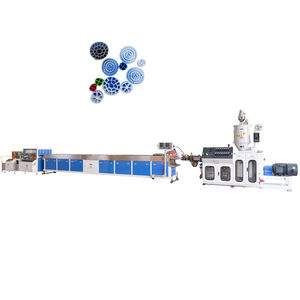

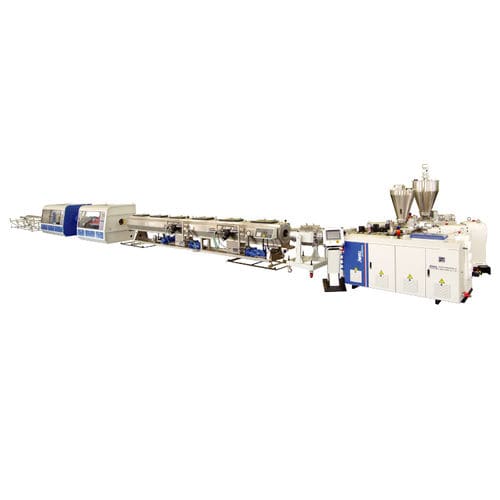

Co-extrusion production of three-layer PVC pipe using two or more SJZ series conic double mainframes. The sandwich layer of the pipe material is high calcium PVC or PVC foaming raw material.

● The main machine adopts Super wear-resistant alloy screw barrel, twin screw feeder feeds evenly, the powder does not build the bridge, extrusion;

● The optimized design of PVC three-layer die, the flow path after chrome-plated high polishing treatment, wear and corrosion resistance, with a special sizing sleeve, production speed, pipe quality;

● The Cutting Machine adopts rotary clamping device, which is suitable for different pipe diameters and avoids the trouble of changing fixture frequently. Equipped with new adjustable floating chamfering mechanism, can be adjusted according to the diameter and wall thickness, chamfering size, cutting, chamfering one-step molding. Closed type dust-absorbing device has better dust-absorbing effect.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jwell Extrusion Machinery Co., Ltd., Shanghai‘s catalogsOther Jwell Extrusion Machinery Co., Ltd., Shanghai products

Plastic extruder

Related Searches

- Jwell extrusion line

- Jwell thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Jwell blow molding machine

- Twin-screw screw extruder

- Rotor pelletizer

- Thermoformer

- Bottle blow moulding machine

- Jwell sheet extrusion line

- Jwell extrusion blow molding machine

- Automated thermoforming machine

- Jwell tube extrusion line

- Plastic pelletizer

- Jwell multilayer extrusion line

- Jwell PVC extrusion line

- Jwell automatic blow molding machine

- Packaging thermoformer

- Waste granulator

- Single-screw screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.