- Production Machines

- Cutting Machine

- Water-jet cutting machine

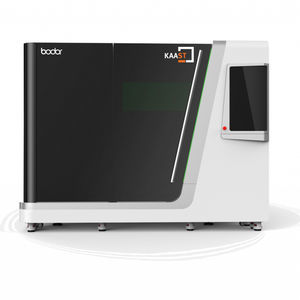

- KAAST Machine Tools Inc.

Abrasive water-jet cutting machine Watersonic for stainless steelfor steelfor aluminum

Add to favorites

Compare this product

Characteristics

- Technology

- abrasive water-jet

- Material

- for stainless steel, for steel, for aluminum, for titanium, for foam, for marble, for carbon fiber, for ceramics, for fiberglass

- Product handled

- for metal pipes

- Control type

- CNC

- Configuration

- 3-axis

- Other characteristics

- high-precision, high-performance, cold

- X travel

1,002 mm, 3,002 mm, 4,002 mm, 6,002 mm

(39.45 in, 118.19 in, 157.56 in, 236.3 in)- Y travel

1,502 mm, 2,002 mm

(59.13 in, 78.82 in)- Z travel

200 mm

(8 in)- Laser power

11 W, 37 W

- Repeatability

0.1 mm

(0.0039 in)- Operating pressure

3,500 bar, 4,000 bar

(50,763.21 psi, 58,015.1 psi)- Overall length

1,400 mm, 1,727 mm, 1,800 mm, 1,900 mm

(55 in, 68 in, 71 in, 75 in)- Overall width

800 mm, 850 mm, 914 mm, 970 mm

(31 in, 33 in, 36 in, 38 in)- Height

900 mm, 955 mm, 1,203 mm, 1,410 mm

(35 in, 38 in, 47 in, 56 in)- Weight

650 kg, 950 kg, 1,180 kg, 1,400 kg

(1,433 lb, 2,094.39 lb, 2,601.45 lb, 3,086.47 lb)

Description

This separation process is an extremely efficient alternative to milling and EDM processing. The method enables material and time-saving nesting of several operations with better cutting performance. Very complex shapes can be manufactured with high precision and clean cut edges without material or surfaces being deformed. Whether single or series production, this cold cutting process guarantees a low cost production with maximum precision and minimum tolerances.

Cold cutting is especially important for the increasing need for production of miniaturized components. Using precision, micro water jet technology intricate workpieces can be cut in many materials with a positioning accuracy of 0.0025 mm (0.00001”) and within the tolerance range of +/- 0.01 mm (0.0004”).

Watersonic: The waterjet cutting system

Welded, corrosion-resistant aluminum frame with gantry

Guideways and drive systems are reliably protected against water and abrasive dust

Brushless servo motors

Stainless steel tank with adjustable water level

Segmented cutting supports

Full high-pressure piping up to 12 meters (474”) between the high pressure pump and cutting table

Protection of the work area by light barriers according to the EU-Directive

A wide range of materials can be processed

Steel/stainless steel, alloyed and non-alloyed, heat resistant alloys, titanium, aluminum, copper, bronze

All kinds of stone: granite, marble, ceramic, concrete

Glass, acrylic, bulletproof glass, security glass and plexiglass

Art and foams

Carbon, carbon fiber and glass fiber

Gaskets, rubber, fabric, leather

Wood, cardboard, etc.

Catalogs

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- CE cutting system

- High-performance cutting system

- Steel cutting system

- Bridge cutting system

- Plasma cutting system

- Stone cutting system

- 3-axis cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.