- Machine-tools

- Finishing Machine

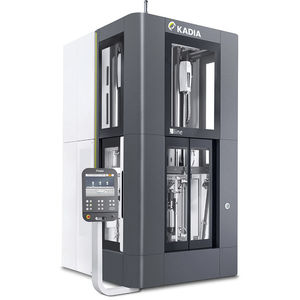

- Deburring honing machine

- KADIA Production

Deburring honing machine X LINEmachiningverticaltwo-spindle

Add to favorites

Compare this product

Characteristics

- Associated function

- deburring, machining

- Spindle orientation

- vertical

- Number of spindles

- two-spindle

- Control type

- NC, automatic

Description

KADIA already presented a prototype of the X line at EMO 2019 in Hanover (YouTube-Video). The feedback from visitors to the booth was incredibly positive, so much so that several orders were received in 2020 despite the pandemic.

The X line is a 2-spindle honing center in gantry design that combines flexibility and productivity. The machine's specialty is the sequential machining of several bores on one workpiece carrier.

Inside the X line, two LH3 honing spindles and pneumatic measuring stations ensure the usual KADIA precision. Deburring stations with automatic brush changers can also be integrated on request.

The bores to be machined are aligned in a highly flexible manner via 3 NC axes: honing, measuring and deburring station form the X-axis as a traversing slide unit, the workpiece carrier handles the positioning movement in the Y- and Z-directions.

The workpiece transport system, a genuine highlight, has a patent pending. The unit was designed with three workpiece carriers as a pallet circulation transfer. With this solution, the X line differs fundamentally from previous NC honing machines: the two machining stations are not approached one after the other, but work simultaneously. As a result, the X line saves a great deal of cycle time. In addition, loading takes place in parallel with the cycle time, so that no separate loading times are included in the total time, as is otherwise the case. This makes the X line an indisputable productivity champion.

Catalogs

X line

4 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.