- Machine-tools

- Finishing Machine

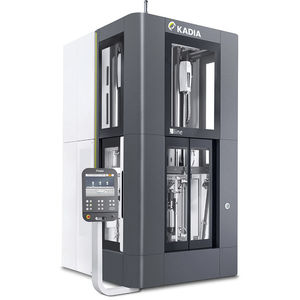

- Multi-spindle honing machine

- KADIA Production

Multi-spindle honing machine T20

Add to favorites

Compare this product

Characteristics

- Number of spindles

- multi-spindle

Description

The best machines for dealing with high volume output

Our multi-spindle honing machines have an excellent reputation worldwide and are always in demand when high-class mass production is required. KADIA machines combine ultra-fine precision with enormous productivity in industrial-scale manufacturing. The appropriate mix and arrangement of our standard modules enables the optimal solution to be implemented for each application. Key features:

* Designed for process capable volume production of high-precision products

* Accuracies in the 0.1 micron range can be attained for diameters, geometries and surfaces

* Extremely high productivity through automated loading and unloading

* Can be configured to meet specific requirements (depending on the upstream machining/processing methods and the desired result)

o Inline transfer with any number of honing stations

o Rotary index table with up to four honing stations

o Pre-checking or pre-gaging system for monitoring incoming workpiece quality

o Post-process gaging stations with feedback control

o Deburring stations can be integrated as required

* Possibility of particularly economical match honing, as replacement for match grinding of the plunger. The bore is honed precisely to the dimensions of the corresponding plunger.

KADIA multi-spindle honing machines no equivalent can offer more advantages.

Example machine

5-spindle machine with inline pallet transfer for match honing and with integral loading cell.

Stations:

* Automatic loading/unloading

* Piston gaging

* Cleaning

* 5 x honing

* 5 x post-process gaging

* 1 x intermediate deburring, 1 x finish deburring

* Blow-off

VIDEO

Catalogs

No catalogs are available for this product.

See all of KADIA Production‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.