- Metrology - Laboratory

- Analytical Instrumentation

- Optical detection system

- KADO Intelligent Technology (Shanghai) Company

- Products

- Catalogs

- News & Trends

- Exhibitions

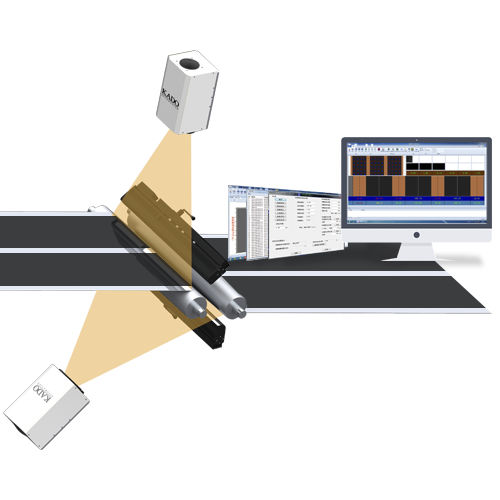

CCD detection system

Add to favorites

Compare this product

Characteristics

- Heating technology

- CCD

Description

Alignment Detection System for Lithium Electricity Industry

Abstract:The system uses the principle of CCD imaging to check 100% on-line the film width, blank (ear width) and the uniformity of the upper and lower coatings. It can also realize closed-loop control through the correction system or servo system, so as to optimize the consistency of the coatings.

1)CCD detection points should be placed on the surface of the roller as far as possible to avoid measurement errors caused by material jitter and instability of equipment tension.

2)The fixing of CCD and light source must be stable and no jitter.

3)Detection scope: customized according to customer needs.

4)Detection accuracy: ≤ ± 0.1mm.

5)The system is suitable for cathode (positive plate) and anode (negative plate) diaphragm measurements,in which the anode has no AT9 coating area.

1)Online monitoring of the width of the material being tested.

2)Data analysis and storage for easy data traceability.

3)Sound and light alarm rules are set to facilitate production control.

4)Multi-level rights management and operational guidance to prevent misuse.

5)Supports up to 300 work order information preservation.

6)Start the check function to prevent the system from detecting false positives.

7)Coating defect detection prevents continuous failure of coated defect .

8)Communication input and output management and signal management.

9)Closed loop control upper and lower coating widths coincide<±0.3mm.

10)System abnormal alarm prompt and abnormal solution guide to facilitate system maintenance.

Other KADO Intelligent Technology (Shanghai) Company products

Vision System

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.