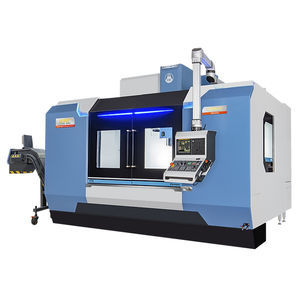

3-axis machining center KMC-RFverticaldouble-columnhigh-rigidity

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- double-column

- Other characteristics

- high-rigidity, direct-drive

- X travel

3,230 mm, 4,230 mm, 5,230 mm, 6,230 mm, 8,230 mm

(127.17 in, 166.54 in, 205.91 in, 245.28 in, 324.02 in)- Y travel

Min.: 2,450 mm

(96.46 in)Max.: 3,850 mm

(151.57 in)- Z travel

1,100 mm

(43.31 in)- Rotational speed

3,500 rpm, 6,000 rpm, 8,000 rpm

(21,991 rad.min-1, 37,699 rad.min-1, 50,265 rad.min-1)- Power

22 kW, 26 kW

(29.91 hp, 35.35 hp)

Description

High Rigidity Double-column Machining Center

All 3 axes travels are fully supported by boxway hereby ensuring the rigidity and stability.

3 axes have larger travel range;extraordinarily Z-axis stroke is 1100mm.

All surfaces that make contact with the slideways are lined with Turcite-B to ensure long lasting and optimum rigidity during heavy cutting conditions.

The mounting brackets for the Y and Z axis ballscrews are integrated with the saddle and crossbeam casting to maximize the rigidity further.

Mechanical safety couplings are used where the drive motors adapt to the ballscrews. These devices greatly minimize damage that may occur during a collision or overload condition.

A ram-type casted spindle head with a cross section of 400x400mm ensures high rigidity and stability under heavy-duty cutting.

Standard 2-station AAC including angular head and vertical head is designed for improving productivity; 30°angle head, extension head and universal head are optionally available for versatile applications.

Catalogs

KMC-RF

10 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Drill

- Rigid CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Electric drill

- Column type CNC machining center

- Cutting CNC machining center

- Horizontal CNC machining center

- Drilling CNC machining center

- BT 40 CNC machining center

- Direct-drive CNC machining center

- 4-axis CNC machining center

- High-speed CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.