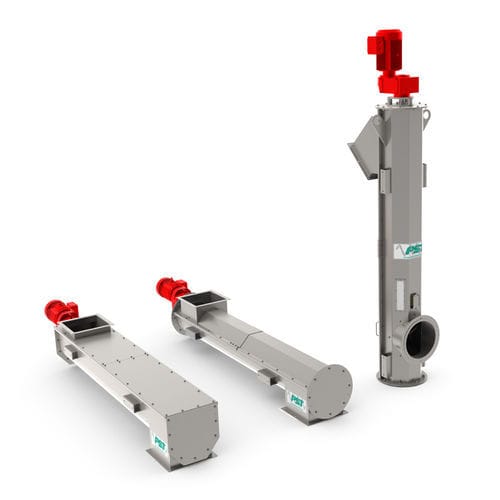

The spiral in Shaftless Spiral Conveyor is made of one or more steel bars without a center shaft. The spiral is lying on the wear liners made of steel bars or wear resistant plastic at the bottom of the trough.

This construction without a center shaft makes it possible to manufacture very long conveyors. The longest one made so far is approximately 62 meters long in horizontal position.

Construction-wise the shaftless spiral conveyor differs of a traditional shafted screw conveyor. In a shaftless spiral conveyor, the screw is made of steel bar(s) and without any center shaft. Contrary of a traditional shafted screw conveyor, the spiral is lying on a wear liner which is made of wear resistant steel bars or plastic.

Construction without a shaft enables to manufacture very long conveyors. In horizontal or slightly inclined position the length of a conveyor can be up to 60 meters. In higher inclination the length can be up to 30-40 meters and in a totally vertical installation up to 20-25 meters – all this with one single spiral! This feature makes spiral conveyors an excellent alternative to belt conveyors, tubular drag conveyors, elevators, pneumatic transport and scraper conveyors.

Shaftless Spiral Conveyor in use

We supply the majority of shaftless spiral conveyors for waste handling, transport of biofuels in renewable energy power plants, mining industry and paper and pulp industry handling of rejects, fiber sludge and bark.

The most common conveyed materials are for example sawdust, pellets, wood chips, bark, knot handling/reject, plastic waste, wood waste, construction waste, municipal waste, sewage sludge and household waste and sludge in biogas plants