Gear grinding center KNG 350 flex HSfor gear teethCNChigh-performance

Add to favorites

Compare this product

Characteristics

- Applications

- for gear teeth, for gears

- Control type

- CNC

- Other characteristics

- high-performance, high-productivity, high-speed, compact

- Spindle speed

Max.: 25,000 rpm

(157,080 rad.min-1)Min.: 0 rpm

(0 rad.min-1)

Description

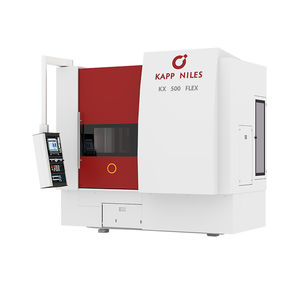

The KNG 350 flex HS is based on a compact, set-up-optimised machine concept and is intended for use in small, medium and large series production of externally toothed components up to 350 mm diameter. The machine is characterised in particular by the highest grinding quality and productivity, even when machining with small tools. Using a high-speed grinding spindle (HS) with a speed of 25,000 rpm, even gear teeth with interfering contours can be ground, requiring tool diameters of min. 55 mm (generating grinding) or 20 mm (profile grinding). The concept also offers full flexibility in the selection of loading and automation solutions. From manual loading to downsize automation to robotic loading. The optionally integrated ring loader ensures the shortest non-productive times and can handle both bore parts and shaft-shaped workpieces. The new functional and ergonomic machine design paired with the innovative user-friendly interface KN grind supports the user during set-up and optimisation of grinding projects.

Catalogs

PRODUCT LINE

29 Pages

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Cylindrical grinding machine

- High-precision grinding machine

- External cylindrical grinding machine

- Internal cylindrical grinding machine

- 3-axis grinding machine

- Stationary grinding machine

- Universal grinding machine

- High-performance grinding machine

- High-speed grinding machine

- Gear grinding machine

- 2-axis grinding machine

- Hydrostatic grinding machine

- CBN grinding machine

- Continuous grinding machine

- Grinding center

- Ball screw grinding machine

- CNC grinding center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.