- Packing - Handling - Logistics

- Storage

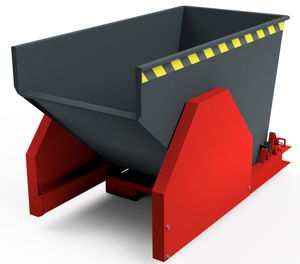

- Metal intermodal container

- Karl H. Bartels GmbH

Metal intermodal container 140.000 seriestransporthandling4-wheel

Add to favorites

Compare this product

Characteristics

- Material

- metal

- Applications

- transport, handling

- Other characteristics

- 4-wheel, large, with handles

- Capacity

1,080 l, 1,500 l, 1,800 l

(285.3 gal, 396.3 gal, 475.5 gal)- Length

1,730 mm, 1,940 mm

(68.11 in, 76.378 in)- Width

844 mm, 1,080 mm

(33.2283 in, 42.5197 in)- Height

1,200 mm, 1,300 mm, 1,600 mm

(47.2441 in, 51.1811 in, 62.9921 in)

Description

Swarf container – used for machine tools for collecting chips

The Bartels swarf container separate chips and coolant via the integrated screen base filter system. Thanks to its moveable polyamide wheels and the pockets for transporting it with a forklift truck, it is ideal for daily production processes. The chip carriage is the ideal collecting container for turning and drilling chips and can be adjusted to your machine.

Advantages of the chip carriage

• Ideal for forklifts with slewing ring

• Economical = Less journeys from machine to container thanks to very large volume

• Liquid-tight with screen base and drain valve

• Available in three different sizes as standard

Individual, custom-made swarf containers

If you need to transport special materials or certain spatial requirements must be met, we can respond to your special wishes in a flexible manner. Our sales representatives are also available for on-site consultation. Our consulting engineer will create individual concepts for you.

Options for swarf containers

• Additional sizes and versions available

• Various colours / custom paint coats in all RAL colours

Operation

Thanks to its large volume, the swarf container can remain under the machine for longer periods, meaning it is very economical! The swarf container is emptied quickly and optimally using the forklift with slewing ring.

Design

• Robust welded construction

• Sheet coating reinforced on all sides

• Handle on operating side

• Screw-in screen base at centre in longitudinal direction, drain with 3/4″ drain valve, includes protective bumper on drain

Catalogs

No catalogs are available for this product.

See all of Karl H. Bartels GmbH‘s catalogsRelated Searches

- Storage container

- Rack system

- Stacking container

- Floor-mounted cupboard

- Storage cupboard

- Transport container

- Metal cupboard

- Storage warehouse rack

- Handling container

- Iso container

- Cabinet with drawer

- Heavy load rack

- Adjustable rack

- Pallet racking

- Container with handles

- Storage iso container

- Rack system with shelves

- Workshop rack system

- Metal intermodal container

- Medium load racking

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.