- Materials - Tools - Components

- Standard Mechanical Component

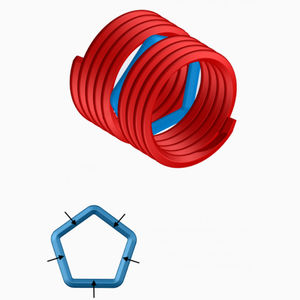

- Threaded insert

- KATO Fastening Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

Threaded insert 304stainless steelround

Add to favorites

Compare this product

Characteristics

- Type

- threaded

- Material

- stainless steel

- Configuration

- round

Description

This is the most popular insert material, and it will satisfy most application requirements for strength, corrosion resistance and temperature capability. The inserts can be used in applications with a temperature range from -320° F to 800° F. Cold rolling the stainless steel wire to a diamond shape work-hardens it to a tensile strength above 200,000 PSI, a hardness of Rc 43-50 and a smooth 8-16 micro-inch finish. The inserts become slightly magnetic from the work-hardening that occurs during the manufacturing process (approx. 2-10 G/O). The insert material is covered by specifications AS7245, NASM8846 and alloy number UNS S30400.

Related Searches

- Hinge

- Metal hinge

- Threaded insert

- Metal insert

- Threaded plug

- Stainless steel lift-off hinge

- Round insert

- Stainless steel insert

- Plastic hinge

- Friction hinge

- Hexagonal plug

- Aluminum insert

- Spring hinge

- Small hinge

- Stainless steel fastener

- Plastic fastener

- Asymmetrical hinge

- Constant-torque hinge

- Locking insert

- Composite insert

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.