- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

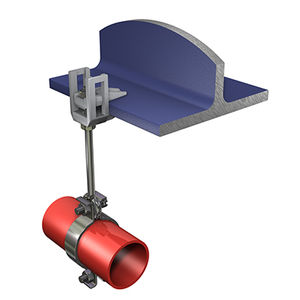

Clamp

Add to favorites

Compare this product

Description

BEAMCLAMP is an extensive range of steel to steel clamping products designed for making steel to steel connections without the need for drilling or welding. The clamping system gives the specifier the peace of mind that once the connection is made it has a guaranteed safe working load, and it also provides flexibility for the user when installing and reduces the overall cost. The system is also ideal for areas where drilling or welding is not allowed or access and power is restricted.

The use of BEAMCLAMPS for steel to steel connections allows for much easier adjustability after the connection has been made by simply loosening the bolts, realigning and re-tightening the bolts again afterwards.

A full list of features can be seen below:

Features of the BeamClamp steel to steel connections compared to welding or drilling and bolting

Third party approval (Lloyds & DIBt)

No special tools or skilled labour required

Guaranteed 5 to 1 Factor of Safety

Easy to adjust on site

No weakening of existing steelwork

No damage to the protective coating of the steelwork

Hot dipped galvanised

Benefits of the BeamClamp steel to steel connections compared to welding or drilling and bolting

Peace of mind when specifying or installing

Savings in installation time and cost

Excellent long term corrosion resistance for external applications

Provides flexibility to allow for site tolerances

BeamClamp Configurator

Try our BeamClamp tool and engineer a BeamClamp connection today.

BeamClamp CAD Drawings

Visit our BEAMCLAMP CAD drawings area to get the most up-to-date CADs available for all BEAMCLAMP products.

VIDEO

Catalogs

No catalogs are available for this product.

See all of KEE SAFETY ‘s catalogsRelated Searches

- Working platform

- Mobile platform

- Clamp

- Access platform

- Metal gate

- Safety acces gate

- Swing acces gate

- Construction site platform

- Steelwork beam clamp

- Vehicle platform

- Steel gate

- Galvanised steel gate

- Handrail

- Aluminium gate

- Truck platform

- Demarcation

- Platform for aeronautical applications

- Chain demarcation

- Railway vehicle platform

- Free-standing demarcation

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.