- Products

- Catalogs

- News & Trends

- Exhibitions

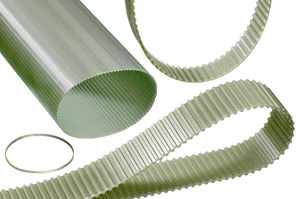

Endless belt timingpolyurethanesteel

Add to favorites

Compare this product

Characteristics

- Type

- endless, timing

- Material

- polyurethane, steel, neoprene®

- Product applications

- positioning

- Sector

- industrial

- Other characteristics

- flexible, aramid, abrasion-resistant

- Length

Min.: 720 mm

(28.35 in)Max.: 22,700 mm

(893.7 in)- Width

100 mm, 150 mm

(3.937 in, 5.906 in)

Description

Polyurethane timing belts, manufactured in state-of-the-art production processes, are made of abrasion-resistant polyurethane and high-strength steel cords, aramid cords or special high flexible HF steel or VA tension cords. The combination of these materials forms the basis for the myriad applications in synchronous power transmission and for transport, conveying and positioning applications. In view of the many possible tooth shapes, materials and production methods, polyurethane timing belts exhibit superior mechanical, chemical and physical properties. Polyurethane timing belts ensure an even distribution of load during power transmission and the transmission of high torques, they have high load capacity, are flexible and, moreover, stand out because of their high longitudinal stiffness and thermal stability.

Polyurethane timing belts are produced in open lengths or welded endless, as sleeve or endless flex belts in almost all lengths and widths.

Open-ended polyurethane timing belts offer very high flexibility for synchronous conveying and positioning applications, and due to the large selection of tooth shapes innumerable application possibilities.

Polyurethane timing belts “V” welded endless

Endless welded timing belts are available in nearly all lengths. They are primarily used in conveying applications.

Polyurethane timing belts “M” in open lengths

Open timing belts are primarily used in linear applications.

Polyurethane molded timing belts (sleeves) are cast in special molds. This ensures very high pitch accuracy along the entire length of the belt, making them particularly suitable for quiet running and high speed.

Related Searches

- Power transmission belt

- Industrial power transmission belt

- Rubber power transmission belt

- Plastic strip

- Timing belt

- Sturdy belt

- Industrial belt

- PU belt

- V belt

- Synchronous power transmission belt

- Flat strip

- Metal pulley

- Oil-resistant power transmission belt

- Flexible belt

- Toothed pulley

- High-performance power transmission belt

- High-resistance power transmission belt

- Abrasion-resistant strip

- Endless power transmission belt

- Belt for the textile industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.