- Production Machines

- Plastics Processing

- Precision mold base

- Kejia (Changxing) Mold Base Manufacturing Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

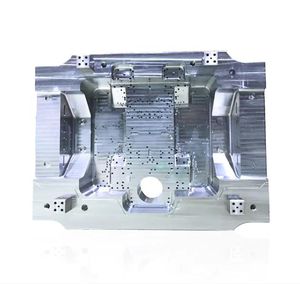

Precision mold base for the automotive industryfor vehicle parts

Add to favorites

Compare this product

Characteristics

- Other characteristics

- precision

- Applications

- for the automotive industry, for vehicle parts

Description

The rear warehouse of the electric vehicle

Product Description: A "new energy vehicle rear compartment mold" refers to the tooling or mold used in the manufacturing process of the rear compartment or interior components of a new energy vehicle (NEV), such as an electric car. This mold is an essential part of the production process for NEVs, which includes electric vehicles (EVs), hybrid vehicles, and other eco-friendly transportation options.

Die casting machine size: - 7000T

Size: - 2905*3460mm

Gross weight per piece: - 70T

The New Energy Vehicle Rear Compartment Mold is a precision tool used in the manufacturing process of new energy vehicles (NEVs), such as electric cars and hybrids. This mold is specifically designed to shape and form various components of the rear compartment, ensuring the production of high-quality and precise interior parts.

Product Specifications:

This mold is compatible with die casting machines with a capacity of 7000 tons, allowing for the efficient production of large and complex rear compartment components.

Key Features:

Precision Mold Design: The mold is intricately designed using computer-aided design (CAD) software to ensure that it accurately replicates the desired shape and dimensions of rear compartment components.

High-Quality Materials: Constructed from high-quality materials, such as steel or aluminum, the mold can withstand the pressure and temperature conditions required for the manufacturing process.

Customization: The mold can be customized to meet the specific requirements of different vehicle models and manufacturers, ensuring a seamless fit for each application..

Other Kejia (Changxing) Mold Base Manufacturing Co., Ltd. products

Die Casting Mold Base

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.