- Production Machines

- Plastics Processing

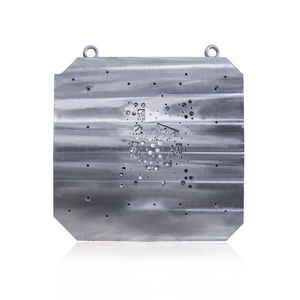

- Injection molding mold base

- Kejia (Changxing) Mold Base Manufacturing Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Injection molding mold base for die castingfor the automotive industryfor vehicle parts

Add to favorites

Compare this product

Characteristics

- Process

- for injection molding, for die casting

- Applications

- for the automotive industry, for vehicle parts

Description

Die casting machine size: - 6000 tons

size: - 2800*3300mm

Gross weight of each piece: - 69T

this " New energy vehicle rear compartment integrated die-cast body structure ” is a key component used in the construction of new energy vehicles, especially in the rear compartment area.

Die Casting Process: This part is manufactured using the die casting process, which involves injecting molten metal into a mold cavity to create highly precise and complex shapes. The size of the die-casting machine used to produce this part is 6000T.

Materials: Typically, such components are made from high-strength materials such as aluminum or magnesium alloys, which are known for their lightweight properties and excellent structural properties. However, the exact materials used may vary depending on the manufacturer's specifications.

Purpose: Rear compartment integrated die-cast body structure has multiple uses in new energy vehicles. It provides structural support to the rear of the vehicle, ensuring it can withstand various loads and stresses.

Advantages:

One of the main advantages of using a one-piece die-cast body structure is that it reduces the need for multiple welded parts, which would weaken the overall structure. A single solid component adds strength and rigidity. Additionally, die casting allows complex shapes and features to be integrated into components.

Application: This component is designed for new energy vehicles, including electric vehicles (EV) and hybrid vehicles. The rear warehouse area is critical to these vehicles, housing batteries, electric drivetrain components and other critical systems.

Other Kejia (Changxing) Mold Base Manufacturing Co., Ltd. products

Die Casting Mold Base

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.