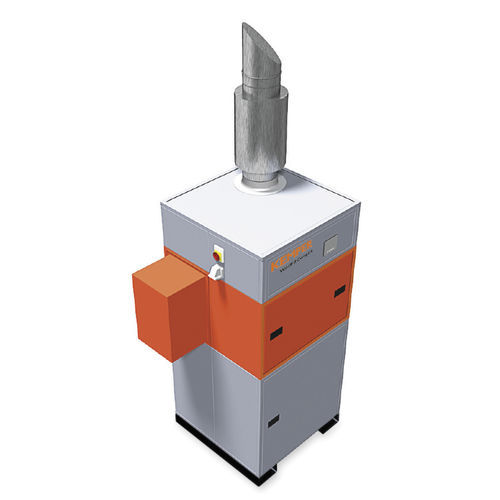

Transportable centralized fume extraction system WeldFil Compactweldinggrindinglaser

Add to favorites

Compare this product

Characteristics

- Mobility

- transportable

- Applications

- welding, grinding, laser

- Filter type

- with self-cleaning filter

- Other characteristics

- dust, automatic, compact

- Airflow

Min.: 1,250 m³/h

(44,143 ft³/h)Max.: 1,800 m³/h

(63,566 ft³/h)- Power

3 kW

(4.08 hp)

Description

The solid yet compact welding smoke extraction system is ideally suited for factory buildings and welding shops with high levels of smoke and dust. Supplied ready to plug in and equipped with forklift pockets and lifting eyes, the WeldFil Compact is quickly installed as a central extraction and filter system for multiple welding work stations, cutting machines and welding robots. The KemTex® ePTFE membrane filter cartridges for ultra-fine dust particles separate particles even below 0.1 µm, and due to the W3/IFA Certification, the extraction filter unit WeldFil Compact is also suitable for use when machining chromium-nickel steel.

Applications

High levels of smoke and dust

Welding and grinding shops

Training centres and robotic welding lines

Laser, plasma and flame cutting systems

Can be installed outdoors

Benefits

Contamination-free dust collection due to compressed air fixation of dust collection containers

Uninterrupted continuous operation due to automatic differential pressure-controlled filter cleaning

Little noise emission due to a low noise level

Considerable energy cost savings by using the automatic extraction volume control

Convenient operation due to intelligent control via touch screen with diagnostic system

Flexible integration of the control system into third-party systems such as cutting equipment due to potential-free contacts

Best health protection for employees by use of KemTex® ePTFE cartridges with surface filtration

Properties

Automatic filter cleaning, pressure-controlled

Control via touch screen

W3/IFA certified

KemTex® ePTFE filter cartridges

Dust collection container with pneumatic lifting device

Automatic extraction volume control (optional)

VIDEO

Catalogs

KEMPER The Catalogue

244 Pages

Related Searches

- Fixed reel

- Spring rewind reel

- Cable reel

- KEMPER industrial fume extractor

- Wire reel

- KEMPER mobile fume extractor

- KEMPER welding fume extractor

- KEMPER fume extractor with extraction arm

- KEMPER stationary fume extractor

- KEMPER extraction arm

- KEMPER dust fume extractor

- Cartridge fume extractor

- KEMPER fixed extraction arm

- KEMPER automatic fume extractor

- KEMPER flexible extraction arm

- Compact fume extractor

- KEMPER smoke extraction arm

- Dust extraction arm

- Floor-standing fume extractor

- Welding fume extraction arm

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.