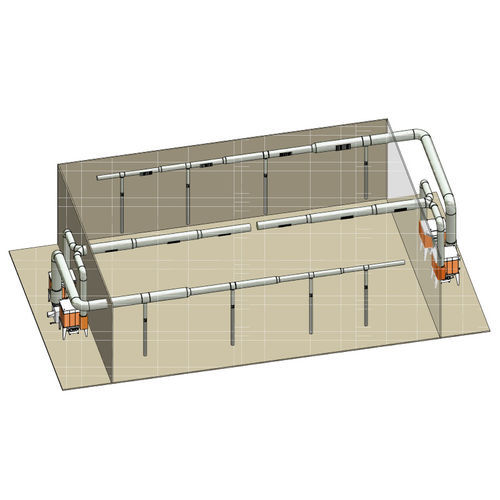

Welding room ventilation system 99 870 100

Add to favorites

Compare this product

Characteristics

- Options

- welding room

Description

The displacement ventilation piping system is connected to a central extraction and filter system. It is suitable for workshops with medium to high levels of smoke and dust where a spot extractor system is not feasible or it is used to supplement spot extractor systems. At the workplaces, the system ensures a constant, low velocity, circulating air stream.

Applications

Medium to high levels of smoke and dust

Workshops where local exhaust ventilation is not possible

To complement local exhaust ventilation systems

Environments with changing sources of smoke and dust

For large work pieces or where work positions are well separated

Benefits

Optimised, low velocity air flow by using thermal air currents

Uninterrupted continuous operation due to automatic differential pressure-controlled filter cleaning

Can be adapted to specific work areas due to a flexible number of outlet pipes

Little noise emission due to a low noise level

Heating costs minimized by air recirculation

Convenient operation due to intelligent control via touch screen with diagnostic system

Contamination free dust collection due to compressed air lift for duct collection container

Properties

Automatic filter cleaning, pressure-controlled

Control via touch screen

KemTex® ePTFE filter cartridges

Dust collection container with pneumatic lifting device

Can be connected to various extraction systems

Can be combined with other intake systems to one extraction system

Adaptable in line with contamination level (outlets)

Low velocity air flow

Economical

Low noise level

VIDEO

Catalogs

No catalogs are available for this product.

See all of KEMPER‘s catalogsRelated Searches

- Mobile platform

- Ventilation unit

- Access platform

- KEMPER curtain

- Heat-recovery ventilation unit

- Ventilation system

- Workshop partition

- Ventilation unit with integrated filtration

- High-efficiency ventilation unit

- Modular partition

- KEMPER strip curtain

- Acoustic partition

- Centralized ventilation unit

- Sliding curtain

- Sound insulating partition

- Folding curtain

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.