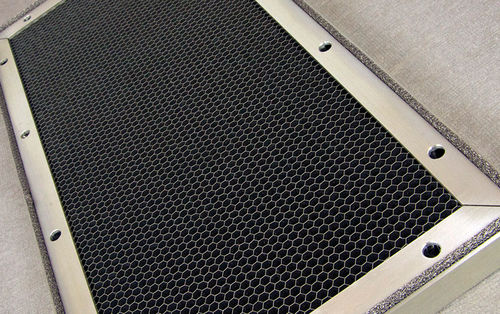

Aluminum ventilation grill honeycombEMC

Add to favorites

Compare this product

Characteristics

- Materials

- aluminum

- Other characteristics

- honeycomb, EMC

Description

Aluminium honeycomb vent panels for air flow consist of an aluminium honeycomb foil held in a rigid extruded aluminium mounting frame. The foil, formed and laminated into a series of honeycomb cells that are glued and perforated or laser welded at the join, ensures a conductive path at each join. Although the foil is conductive in all directions, to enhance EMI performance, two pieces of honeycomb polarised at 90° to each other are recommended.

Shielding is achieved by using waveguide beyond cut off design principles (Honeycomb Cell dia X length by 4). The frame can be supplied with an integral or separate EMI/RFI gasket and can be treated with a variety of finishes to provide corrosion protection or improve conductivity.

An extensive range of aluminium extrusion mounting frames are available from stock offering a choice of mounting methods and sizes. Available as custom sizes with no additional cost. Frames can be supplied with fixing holes or captive threaded inserts to aid mounting. Honeycomb can be supplied in several configurations to suit different EMI/RFI Shielding performance requirements. Such as straight through, polarized and a choice of cell size.

Standard perforated honeycomb is available with 30˚, 45˚, 60˚ and 90˚ angles from stock and Laser welded aluminium honeycomb is also available to special order.

For vulnerable situations weld mesh or expanded aluminium kick plates can be fitted.

Removable dust filters and integral insect screens can also be provided.

Catalogs

No catalogs are available for this product.

See all of Kemtron‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.