- Power Transmission - Mechanical components

- Mechanical Transmission

- Friction brake

- Kendrion (Villingen) GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

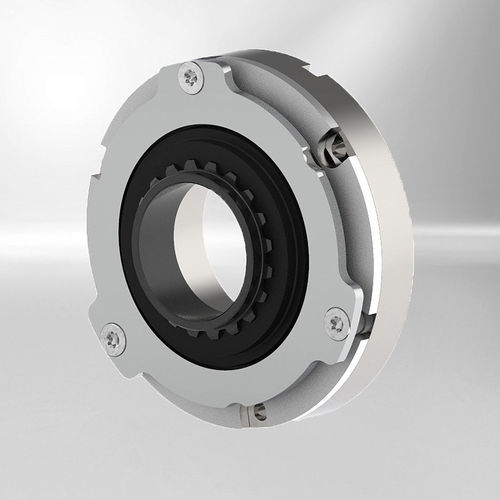

Failsafe brake Servo Slim Linefrictionspring activatedsafety

Add to favorites

Compare this product

Characteristics

- Type

- friction

- Operation

- spring activated

- Other characteristics

- safety, failsafe, DC voltage, hollow-shaft, for servo motors, for collaborative robots, slim

- Torque

Max.: 8 Nm

(5.9005 ft.lb)Min.: 0.27 Nm

(0.1991 ft.lb)- Rotational speed

2,500 rpm, 3,000 rpm, 4,000 rpm, 5,000 rpm, 6,000 rpm

(15,707.96 rad.min-1, 18,849.56 rad.min-1, 25,132.74 rad.min-1, 31,415.93 rad.min-1, 37,699.11 rad.min-1)- Power

Max.: 27.2 W

Min.: 5.8 W

Description

Fail-Safe spring applied brake with slim design

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives.

The optimal solution for robotics

There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

For decades Kendrion has been supplying brakes for industrial robots with loads higher than 20 kg. In order to be able to serve the booming market of smaller robots the brake specialist has invested a lot into the research and development of suitable brakes for robotics applications in recent years. With many years of experience and the latest findings from the market ideally suited solutions for robotics have been developed.

Manufacturing technology

A patented manufacturing technology provides the basis for this solution: In case of conventional spring-applied brakes the production-related tolerances of the air gap, i.e. the distance between friction disc and armature plate, must be taken into account

Catalogs

Other Kendrion (Villingen) GmbH products

Spring-applied brakes

Related Searches

- Kendrion friction brake

- Kendrion spring brake

- Kendrion disc brake

- Kendrion electromagnetic brake

- Friction clutch

- Electromagnetic clutch

- Kendrion safety brake

- Disc clutch

- Emergency brake

- Kendrion spring activated brake

- Clutch and brake

- Failsafe brake

- Friction clutch and brake

- Manual brake

- Motor brake

- Manual release brake

- Kendrion robust brake

- Adjustable brake

- Multiple-disc brake

- Double brake

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.