- Machine-tools

- Cutting Tool

- Solid drill bit

- Kennametal

- Products

- Catalogs

- News & Trends

- Exhibitions

Solid drill bit KenDrill™ SGLfor stainless steelcarbidedeep hole

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Drilled material

- for stainless steel

- Drill bit material

- carbide

- Other characteristics

- coated, high-performance, with internal coolant, deep hole

- Diameter

Max.: 19.05 mm

(0.75 in)Min.: 3.97 mm

(0.16 in)- Length

Max.: 76 mm

(2.99 in)Min.: 23 mm

(0.91 in)

Description

SGL drills with through coolant for stainless steel and high-temperature alloys.

By combining unique Kennametal features such as the all new SGL-Point-Geometry with a patented gashing, an unique Flute Design and a best in class coating into one tool, the B/K21*SGL drill is the ultimate high volume production tool.

All new SGL point geometry with improved web thinning and patented gashing which migrate in a straight cutting edge enables high cutting parameters (feeds), improves hole quality and creates controlled chips which leads to a reliable performance.

KCMS15 grade is a Monolayer PVD AlTiN coated fine grain carbide with superior surface finish. First choice for stainless steel, high-temperature resistant materials. The coating offers high hardness and excellent wear resistance as well as enhanced high-temperature properties increasing its applicability also to MQL machining of steel.

The highly polished surface ensures superior chip evacuation even when low-pressure coolant is applied.

Ideal point angle and tolerance make the B/K21_SGL series the preffered pilot drill for B27_SGL series Solid Carbide deep Hole Drills.

Catalogs

No catalogs are available for this product.

See all of Kennametal‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Cast iron milling tool

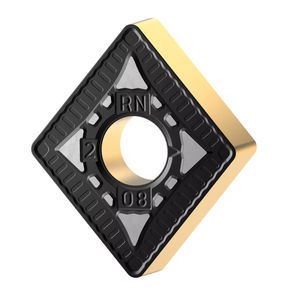

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Roughing milling tool

- Carbide drilling tool

- Helix angle milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.