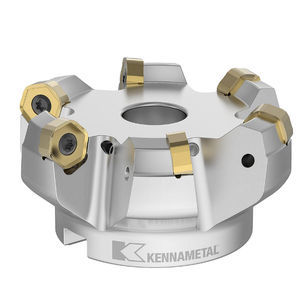

Shoulder milling cutter 4-12 KT™tangentialinsertroughing

Add to favorites

Compare this product

Characteristics

- Geometry

- tangential

- Construction

- insert

- Type

- finishing, roughing, shoulder

- Treated material

- for steel, for cast iron

- Other characteristics

- cutting edge

Description

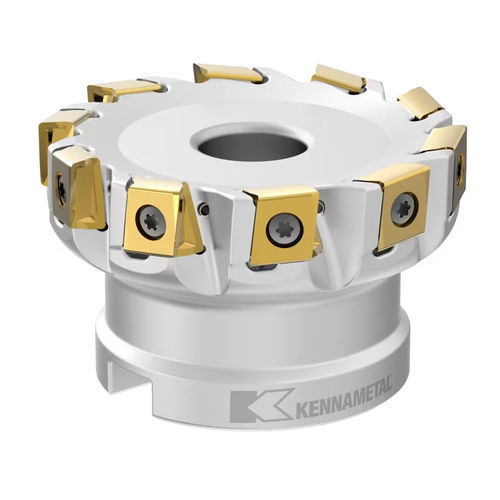

• Mill 4-12KT requires up to 15% less horsepower, enabling increased feed rates, even on 40 taper machines.

• The proprietary insert design - featuring a triangular shaped margin - provides unprecedented stability in steel and cast iron applications.

• Excellent floor finishes due to minimal axial runout.

• With 7 grades, 7 corner radii, and depth-of-cut range up to .472" (12mm), the program offers versatility to cover many shoulder milling applications.

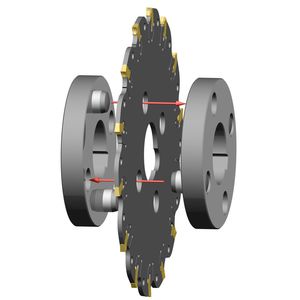

• Left hand inserts with multiple corner nose radii for tailormade slot mills.

• Fine pitch cutters for high productivity with low radial depth of cut (ae) when roughing and finishing in cast iron.

• Reinforced HD Geometry inserts provide higher stability and lower risk of breakage in heavy and interrupted cuts.

• Precision pressed PU Geometry for the lowest cost per cutting edge

• Strong cutting edges for higher productivity and increased MRRs

Handle Severely Interrupted Cuts with Ease

The strong cutting edge of the Mill 4-12KT inserts were designed to overcome challenging applications, heavy cuts and the most severe interruptions. Even after cutting "Swiss cheese," there was no visible wear and no chipping. If you have challenging applications to overcome, then this tangential milling cutter is the way to go.

Catalogs

INNOVATIONS 2020

84 Pages

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

- Helix angle milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.