- Machine-tools

- Machining Center

- 5-axis machining center

- Kern Microtechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

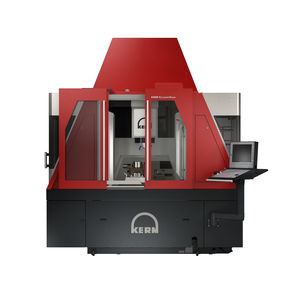

5-axis CNC machining center KERN Micro Varioverticaldentalfor medical applications

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Applications

- dental, for medical applications, for the automobile industry, for the mold industry

- Other characteristics

- compact, high-precision, high-productivity, for production, for micro-machining

- X travel

350 mm

(13.78 in)- Y travel

220 mm

(8.66 in)- Z travel

250 mm

(9.84 in)- Rotational speed

30,000 rpm, 42,000 rpm, 50,000 rpm

(188,496 rad.min-1, 263,894 rad.min-1, 314,159 rad.min-1)- Power

6 kW, 15 kW

(8.16 hp, 20.39 hp)

Description

Compact, extremely precise, incredibly powerful

With its new design and advanced developments, the second generation of the KERN Micro sets new standards in flexibility, precision and productivity. Ultra-compact, trimmed for productivity and precision, flexible and application-oriented, the KERN Micro Vario generates the decisive competitive advantage – permanently and efficiently.

– Compact design and small footprint of only 4 qm /43 sqft

– Supreme machine stability with the advanced KERN Temperature Management

– High productivity with unmatched accuracy

– Best quality, flexibility and competitiveness

– Multi-shift operation with no need for operator with integrated changer for up to 210 tools and a maximum of 60 workpieces

– Certified interfaces for additional accessories and automation systems

– Management and maintenance during operation without interruption while machine is running

Flexible platform for highest demands

With the sophisticated machine design, the unique KERN temperature management and the high-end components, the machine reliably delivers the well-known KERN precision and repeatability. The KERN Micro Vario is at home in the industrial environment. It is reliable, robust and durable – for every kind of application. Special editions for the perfect machining of graphite or for zirconia machining are also available on the basis of a KERN Micro Vario.

When productivity and precision really count

The KERN Micro is ideal for all industries requiring ultra-high precision in serial production.

– Tool/mold production

– Automotive

– Dental equipment

– Medical equipment

– Micromechanics and the watch industry

– Research and development

Related Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- CNC machining center with pallet changer

- Precision CNC milling machine

- Compact CNC machining center

- Machining center for the automobile industry

- 5-axis CNC milling machine

- High-precision CNC milling machine

- CNC machining center with moving table

- Medical CNC machining center

- CNC milling machine with pallet changer

- CNC milling machine for the mold industry

- CNC milling center for the mold industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.